Everything posted by 240260280z

-

Series One with turbo diesel

I always liked the shoe-shaped gen1 Honda Insight, low mass, low frontal area, aero shape and efficient motor. Rip out the electric stuff and stick in an efficient 4 banger diesel.

-

Weather Seal Refresh

Just got this product from Honda for my S2000 softop's rubber seals. It is great. It refreshes and protects the rubber but does not leave a greasy mess (after a day or two). To apply just put some on a shop rag and rub into the seal and that is all. I like it way better than the silicon sprays that I used in the past. Honda Part Number: 08798-9013

-

Anyone familiar with X1/9s?

Fiat X1/9's For Sale on Craigslist, EBAY and Kijiji

-

Anyone familiar with X1/9s?

One passed me when I was a kid walking along the highway living in the stix. Instantly fell in love with 2 seaters.

-

Dual Weber Pictures/Hello

r o f l LMAO

-

Pics from Today's Z Gathering

Looks like it was a beautiful day! Thanks for the pics!

-

Recommended for Cleaning Clear Coated Rims

I cleaned clear coated aluminum rims today. At first I just used soap, 3 different scrub brushes and a scotchbrite pad. There were dark spots in the "corners" and deep in the wheel where the brake dust would not come off even with the scotchbrite pad (rougher sand cast areas). I had a wheel solution that I forgot about and gave it a try. Wow, it cleaned everything with just a gentle srubbing action after a 30 second soak. I strongly recommended it: Meguiar's Hot Rims All Wheel Cleaner. It works.

- Dual Weber Pictures/Hello

-

Dual Weber Pictures/Hello

... that is ancient Vulcan logic for sure. Too bad you could not lift is up like a hood... that would turn heads at a car show.

-

NJ Z Car Club Meeting Sunday July 10 at 12 Noon Green Knoll Grill (Just after F1)

DIRECTIONS or MAP to the Green Knoll Grill in Bridgewater, NJ Sunday, July 10 at Noon See you at the the Green Knoll Grill Open to members and "not yet" members! ** Topics of discussion will be: Review events for rest of the year Discuss other activities -- in South/North Jersey? Suggestions for connecting with other Z enthusiasts? Our annual picnic and car show details New member T-shirts Our famous "Talkin' 'bout Z cars" in the parking lot!! ...and much more!!

-

Customizing my MSA flanged exhaust

Congrats! You just joined the group of us who suffered through the same drone-ing MSA kit's trial-and-error solution. Look on the bright side ... at least your dual vertical outlet looks darn cool!

-

Dual Weber Pictures/Hello

Klingonish

-

Hell-o from the Middle-of-Nowhere, Montana

My 77 280z came from Montana For most electrical problems, simply cleaning corrosion from connectors and fuses usually does the trick.

-

FS4W71A Transmission Assembly Photos (Jan 1971 240z)

- FS4W71A Transmission Assembly Photos (Jan 1971 240z)

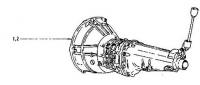

Closed up and ready for installation. A coat of silver paint and it will look mighty purdy. Note the disassembled motor parts and the differential ready to go.- FS4W71A Transmission Assembly Photos (Jan 1971 240z)

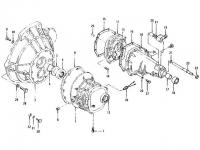

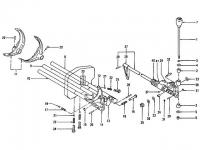

Shot of striker rod (lurking in the dark like a moray eel) and the shifter rod ends where it engages. Note that the reverse rod is forward and engaged. When reassembling, all shifter rods should be in neutral. Rear housing in place. I reused the paper gaskets. I just scrapped off the "gunks and chunks" with fingernail and wiped with alcohol. I used Pematex Aviation Gasket Maker (applied to both metal surfaces and both sides of the gasket). Middle housing being positioned. Front view of middle housing in place. I used lithium grease on shifter rods and gears to help but it is not really needed. The reverse assembly protection mechanism. The unit was seized. There was no corrosion and no significant signs of wear however I could not shift into reverse. To correct the problem I has to file the plunger/shaft part on each side of the "mushroom" end and I also had to cut two coils from the small thin spring. You can see the groove in the plunger/shaft part where the ball bearing seats. Front main bearing. The circular clip is installed that holds it in place. Two bearing shims. The new front seal is in place. Countershaft bearing shim in place. I used lithium grease to hold it in place. The main drive bearing shim gets installed in the front bell housing just on top of the seal. Speedo gear in place. I used antiseize above the o-ring to keep water out and make next-time removal easier. Front bell housing bolted in place. Same routine for the associated gasket on the other side.- FS4W71A Transmission Assembly Photos (Jan 1971 240z)

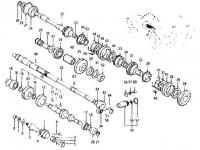

Back side of front bell housing. Front seal is removed New rear seal ready for installation. This is a black-dragon beck/arnley part that is smaller in thickness than the original Nissan part. Guts More Guts Where the striker rod connects to push/pull the rods/forks. Top is 1&2 gear, Middle is 3&4 gear, bottom is reverse with a protective button and spring to prevent accidental shifts into reverse. This protective mechanism was seized on this transmission and had to be disassembled and filed as well as a spring shortened to work again. The spring that was shortened is inside that point metal part of the housing attached to the end of the reverse rod. It has a ball bearing mechanism similar to those in the shift rods. Front bearings. Big main drive bearing on top and smaller countershaft on bottom More gears. The bolts in the main plate/adapter hold small ball bearings and springs. These hold the shifting rods in place. You can see a groove in the lower shift rod (reverse) where the ball bearing engages. This occurs when the rod is pushed forward (since the stick shift is a lever, pulling the stick back into reverse actually pushes the rod forward. More details Even more. Note the brass syncros. GL5 gear oil likes to eat these so always use GL-4 in your transmission and GL-5 in the differential. Reverse Gear- FS4W71A Transmission Assembly Photos (Jan 1971 240z)

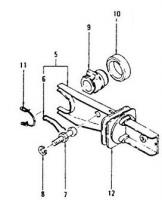

I just refreshed a transmission and took pics as I disassembled and reassembled. There aren't many pics on the net so this will hopefully help others. Parts: 3 Gaskets, 2 front bearing shims, 1 front bearing clip, 18 M8 X 1.25mm bolts, drain/fill plugs, speedo gear w locking clip and bolt. Not included: throwout bearing, throwout collar, fork, spring clips, slave cylinder (will be added to post later) Rear most housing with the famous "monkey motion" assembly. Inside the rear housing. You can see the striker rod that is driven by the money parts. It was bent and slightly deformed in this old transmission making removal of the rod and the rear part of the housing difficult. Some filing helped sort it out. End of transmission where the drive shaft connects. The rear seal is removed. Hole where speedo gear connects. It was difficult to remove the gear. I had to spin it with a pipe wrench. The speedo is sealed with an O-ring and a simple clip holds it in place. Here is the speedo gear. The area above the o-ring corrodes overtime and causes it's resistance to removal. When reassembling I used lots of antiseize above the o-ring and lithium grease below it. Front face of the middle housing Inside the middle housing. Not much exciting except for the drain and filler plugs Front bell housing Another shot of bell housing. It is easy to see the tube where the throwout bearing and collar slide up and down. I had to use a scotchbrite pad to clean it up as it was corroded. Before installation I will use a high temperature urea based grease for these parts. You can also see the pivot for the clutch fork (removable) and the hole where the fork is connected. I chased all holes and bolts when dissembled and used lots of anti-seize when reassembling.- the paint mask for my 240Z, what do ya think

Creative- Lucky 4000 mile Z

Wow that is a time capsule! Thanks for the photos.- Lucky 4000 mile Z

see! Great Z community in your neck of the woods! btw Jim is a rock/pillar/ great guy in the Z community!- Lucky 4000 mile Z

I assume you are in the Calgary Z Club? If not: http://www.calgaryzclub.ca/ great catch!- Engine Compartment Bath?

White lithium grease works fine on plastic so I like to use it on these ball and socket joints. (It also works great on poly bushings)- Halfshaft internal ball bearing hardness

Great to see you here Jeffrey. The only advice I can give is to try and reassemble again but switch the outer shaft 180degrees. The shafts on the 71 240z that I am reassembling have only 2 plastic spacers (like in the diagram above) however there are diagrams with 3 spacers as well as many photos online with 3 spacers. I also remember reading that 280z's had two sizes (a shorter and longer shaft) because the R200 is "fatter" on the left side. Maybe the previous ower(s) swapped out your 180 shafts with 280 shafts. Thanks for confirming bearing size too!- Nobody makes replacement proportioning valves?

Yes a refurbish is recommended. You can put a brass wire wheel on a drill and clean up the outside nicely too. - FS4W71A Transmission Assembly Photos (Jan 1971 240z)

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.