Everything posted by 240260280z

-

Solution for my brake problems: Am I on the right track?

-

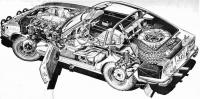

Transparent Rally Artwork

-

noob valve adjusting on 1978 280z

These are easy cars to work on. Your effort also unearthed a new fault that may become common to these aging cars. It will help others in the future. Now enjoy driving Philip

-

2 cool 2 not pass on

Yeah UFO... loved it when I was 5 years old... ever see the pilot movie called Doppleganger? http://www.imdb.com/title/tt0064519/

-

2 cool 2 not pass on

Cool, he made the Shuttle on Star Trek... thus the link http://www.c-we.com/piranha/GeneWinfield.htm

-

2 cool 2 not pass on

From my fav Brit sci-fi series:

-

2 cool 2 not pass on

- 240Z based 2000 GT replica

- 240Z based 2000 GT replica

Luv it... but 2009? did it ever get off the ground?- Atf?

this thread will help you get the cob webs out safely http://www.classiczcars.com/forums/showthread.php?42066-Turning-Over-240Z-engine- Atf?

Same stuff. It will work down into rings and oil/lube and maybe break up rust ring-wall bonding.- Total Brake System Refresh

Yes 280z pads will work. Here is another supplier: http://www.thezstore.com/page/TZS/CTGY/SBC03 for brake line it is 3/16" dia and the fittings are "Japanese" M10 X 1mm Copper Nickel Steel Alloy is good stuff. All steel will rust. Stainless steel is too hard to work with for most DIY-ers- Engine Compartment Bath?

CD2 is not an oil as Threehz mentions. I thinks oils will trap dust and dirt. CD2 drys hard so it does not do this. TIP: If you want to rinse something but have it dry quicker (like acid treated metal or wet sanded metal), rinse with boiling water.- noob valve adjusting on 1978 280z

Bonzi- Hello! I am a brand new member and I have questions! Here goes:

I can ring you and answer some questions. Just send me a private message with your number and time zone and a convenient time to call.- Total Brake System Refresh

The lowest cost overhaul would be to - replace the two rear wheel cylinder seals (kit with rubber parts ~$6.95 each side) http://www.blackdragonauto.com/icatalog/zr/full.aspx?Page=53 - replace rear shoes ~ $49.95 - replace rear spring kit ~$9.95 - replace master brake cylinder seals (kit with rubber parts ~$9.95) - replace front pads ~19.95 http://www.blackdragonauto.com/icatalog/zr/full.aspx?Page=51 http://www.blackdragonauto.com/icatalog/zr/full.aspx?Page=55 Hope your front discs,rear drums, caliper, and master vac brake booster are ok. You will need brake fluid and caliper grease.- mini cooper

- Replacing the factory radio

just keep the old parts in a box... reinstall if you ever sell to someone who whats the original parts- mini cooper

My experience: The convertibles have big blind spots. The dash and gauges are too hard to look at. Here is a great way to see real world opinions from owners. Just read about 30 reviews on any car you consider and you will see trends such as : "bad fuel mileage" or "transmission leak" or "no problems just gotta change oil" etc. I did not read any of the 2004 Mini reviews in the link below but a few months ago but I did for some checks for Honda automatics from 2000-2003...the site saved me from making a bad recommendation to a friend: http://www.edmunds.com/mini/cooper/2004/consumer-reviews.html Maybe your wife would like a Toyota Celica, Honda S2000, Mazda Miata, Toyota MR2 Spyder or Civic Coupe with leather instead of Mini?- Firing order, timing mark, rotor position, any ideas?

Yes, for a quick test just move the plugs 180: Right now you have 153624 Rearrange to 624153 Popping intake could be timing or running lean- Engine Compartment Bath?

Glad to help. Yes I have a 77 280z as well. Lots of pics here : http://atlanticz.ca/zclub/techtips/ and some here:http://atlanticz.ca/zclub/members/philippilgrim/- Engine Compartment Bath?

- Firing order, timing mark, rotor position, any ideas?

- Distributor shaft from Oil pump could be 180 degrees out and the piston one at TDC could simply be top of exhaust stroke rather than top of the compression stroke.... recheck - distributor rotor will have swept past #1 post by ~ 10 degrees advance when crank is at TDC.- Engine Compartment Bath?

Another before and after CD2 is dry (sort of matt finish)- Engine Compartment Bath?

CD2 is incredible.That and Redline MTL are the only two "snake oil" bottles that work. I just used CD2 on my S2000 and I am still amazed every time I open the hood. Here is someone else's S2000 example (CD2 Still Wet) - 240Z based 2000 GT replica

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.