Everything posted by ZSaint

-

DynoMax Super Turbo

Great stuff. I will look at the info you provided. I want to make certain that this system is not LOUD. I do not want to sound like a fart can!

-

DynoMax Super Turbo

I know there are new studies out that show improvement in torque and hp ratings for larger exhaust pipes. These have been done on V/8 cars, of course. I saw (Mopar Muscle) a Challenger that had an X-pipe with a 2 1/4" system changed to a 3" system. They picked up 12 hp and I think 16 hp in torque improvement. This was on a 300 hp crate 360 ci engine. That is a 4-5% gain. I have not seen any chassis dyno work for a similar change on the L6 engine. I might be interesting to know the outcome. I am installing a 2 1/2" system on my '71 240Z (carbureted 280ZX engine). It seems like the correct size for the exhaust system. I will use the header (6-2-1) pipe size (2 1/2") for the entire system. I cannot see the advantage in running a larger system on a street car. I think this will breathe very well at 6,750!

-

240z speaker setup. Help me plz :P

Wait until this fellow discovers that the Z only has an AM radio. (Well most of them!) Yowsa, yowsa, yowsa!

-

DynoMax Super Turbo

I looked at the Dynomax webpage and could not find the #17723 turbo muffler. I did find a 17733 that seemed correct. I just do not know about the inlet/outlet needs. Maybe someone can get Dynomax to tell us the correct number. Someone sent them a message. Maybe they will respond.

-

DynoMax Super Turbo

I looked at some posts about these mufflers. I did not have my Z very long before I took it apart. Which way do these mufflers go.... inlet/outlet? I had an old stock muffler on it and I do not remember the set-up. Is the inlet in the middle and the outlet on the bottom? :paranoid: I found a pic of the stock muffler. It was round and the inlet was at the bottom and the outlet was at the top. What about the Dynomax mufflers... Do I want the outlet on top or in the middle? I am guessing I want the inlet to be in the center, correct?

-

My tub is blue!

Thank you for the info. I will try it. I know this is for the "Photo Gallary". Will I be able to put pics in my posts, also?

-

My tub is blue!

I have the pics if you will show me how to post them. I have tried on this forum and it is too difficult for those of us who are computer stupid. Why is it so easy on other forums and so difficult on this forum? I guess it is only for the brilliant computer nerds, right?

-

My tub is blue!

]My tub is finished with the exception of where the rotisserie was and final buffing. They guys a re leaving it on the rotisserie and trailering it to my shop. Now the hard work begins! The body/paint guy will do the fenders, doors, hatch, hood, etc, over the next month and have it ready when the car is back on it's wheels. The engine should be finished in a couple of weeks. I will put those pieces together as time allows. It will be a busy spring and summer for this old racer.

-

Changing from a 180 to R200. Need some part pics?

I will send you the bucks to get the correct piece. I am leaving for CA in 3 days so please send me your address. "reelsaint@comcast.net" I knew there was a reason for joining this Z site!

-

Changing from a 180 to R200. Need some part pics?

I am changing my 180 to a R200 Limited Slip diff. I have the correct mustache bar. The info says I need another front mount and a rear mount. The rear frame member I have is straight across. The drawing shows this piece to be curved (around the diff cover?). Anyone got a pic of this part and the front mount? I need to know what to look for and what to ask for. Thanks!

-

Engine data needed...?

Thank you Phred. I do remember breaking a piston at Sears Point. I was trying to get all the way down the hill in 4th gear. I remember it started to rattle and I shut her down. Then you guys built the killer dual 4 bbl engine. That thing would rev to 9,000 when I needed it. Those were the days....

-

Engine data needed...?

I am building a 280 engine. How much clearance do I need in the piston for the wrist pins? (I have floated the rod/wristpins) One piston seems really tight with the wrist pin clearance being marginal. Will I need to relieve that piston so it is like the others? Or, as long as it pushes into the piston will it be OK?

-

Dip

I had the doors, hood, rear hatch, engine compartment, wheel wells, etc. blasted with these shells. It takes the paint and eveything else off. (It does not remove rust) It is ready to paint because there is no abrasive action. The metal is very smooth and ready to prep. The painter loves these shells! He recommended the place and the pieces came out looking like new. I sand blasted the few spots that had surface rust on them. No rust in my Z! Yeah, baby!

-

NE1 know what the engine oil pan steel reinforcing strips are called?

I need to know what Datsun/Nissan calls their flat steel strips that reinforce the oil pan against the block. I cannot find anything about them in the manual. Looking for the technical name for these steel strips.

-

ARP rod bolt torque?

I am liking the 30# torgue for the 8mm bolts. I will use the stretch factor to make certain we have sufficient torgue. Thanks guys!

-

ARP rod bolt torque?

I just purchased a set of 8mm 240 rods for my new engine. The rods have been lightened and have had ARP bolts installed. What is the proper torque for these rod bolts? They are 8mm.

-

Got info on Camshaft. EN1 know about this cam?

Thanks for the cam specs. I did not see any cam that has the lower lift and 260` duration. This must be a very mild cam. Ouch!

-

What about this tranny, diff concern for early and late Z's??

I have the later mustache bar which allows the diff to move rearward. I am hoping the driveshaft will work. I just had it powder coated and put new u-joints in it. I will weld the gearshift rod to give me the extra clearance. I am hoping the D/S works!

-

Got info on Camshaft. EN1 know about this cam?

No one has this Web cam or something similar????

-

Stiff springs, standard strut inserts

When I first started autocrossing many, many years ago, I had a MGA. It had friction shocks on it. I took them out and drained the thin oil out of them and put in STP. It did not work as it would chatter over bumps and I would lift wheels all of the time. The shocks simply no longer worked. I once again changed the oil to 10wt and they worked very well. They were considerably stiffer than the original shock 'valving' and were satisifactory for my needs. I tell this story to remind people that changing from light/5wt oil to 30wt oil is a tremenduous change in viscousity. Be careful with these changes... a lot of bad things happen (to the shock valving) when they are too stiff.

-

What about this tranny, diff concern for early and late Z's??

I have been reading some posts about the difference between older and newer Z diff and tranny positions. I understand that my early (2-71) Z has the diff mounted a bit shorter (2 cm) than the later Z's. No one at the shop has talked about changing the driveshaft or the center console mods. I have a 83 Maxima long O/D 5-speed and a R-200 L/S with the stock '71 drive shaft all ready to install. Will I have problems getting this combo to work in a '71 Z?

-

Fan clutch bearing

Most bearings can be found at a bearing shop. They will mic the inside and outside and the thickness and match it up to their stock. It will be a lot cheaper than getting it from Nissan. Most bearings are metric sized and unless it is a very weird application they will have (or can order) the bearing.

-

Fan clutch bearing

Wow! I do not know the answer to your question. If the "oil" is gone then the only factor that will cause the shaft to not run free must be the bearing. I am guessing you need another clutch. Why do you not want the fan clutch to kick in when it is hot? The viscous fan does not turn with the rpm's of the engine when you rev the engine. That is how it saves HP. It does turn when you are running a steady rate. It will not run 7K when you turn 7K. I am not certain what you are doing by having the fan, "freewheel". Why not just remove the fan?

-

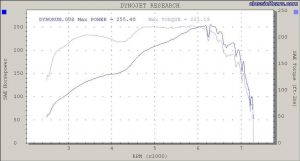

June 03 Dyno Run

How do you explain that 'dip' at 6,200 rpm? Fuel problems? Ignition? Very interesting sheet. Good power from 4,000-6,400. What camshaft are you running?

-

L24 L26 L28 Dyno results

I think it has to do with the "pull of the moon". 'Down there' is a looong way to go and the dyno's are upside down. That why they do not work as well. I remember coming home from Sidney and it took 14 1/2 hours. I would love to be in a racecar for 14 hours but never again in an airplane. GAWD it is a long trip! It is a lovely place, however, and the ride was worth it. G'Day