Everything posted by Jeff G 78

-

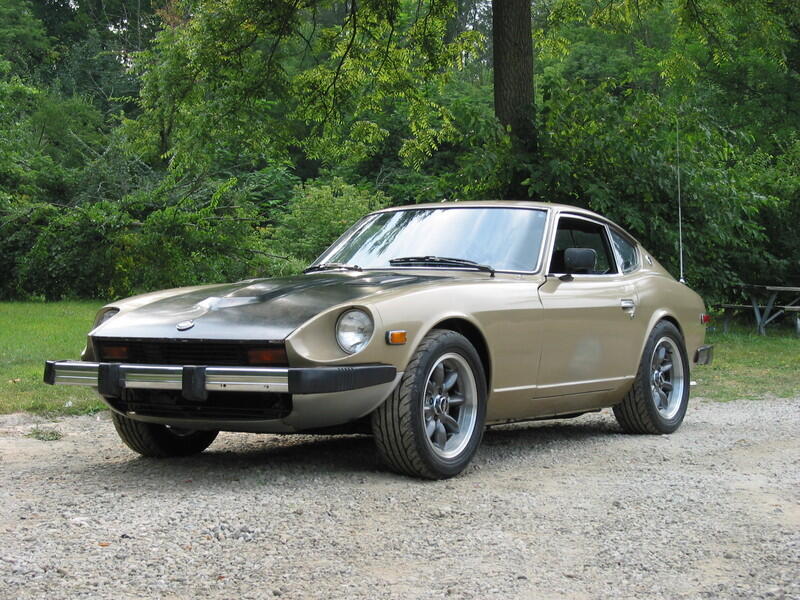

1976 280Z Restoration Project

Sorry to see your parts looking like that. At least you should end up with a killer engine. It could be worse. If you want to feel better, price a Porsche engine rebuild. My 996 WILL need a rebuild at some point and I'm looking at about $20k for a pretty stock rebuild. Okay, but it's a 911, so the car is worth a bunch of money right? Yep, it's worth about $20k 😞 My car has 143,000 miles on it and the clock is ticking.

-

Only those with strong stomachs look

I had a '75 that was gone from the base of the windshield all the way to the fuel tank on the RH side. The tunnel and a bit of the rocker was the only thing holding the car together.

-

Let's show vintage racing pictures. I'll start.

-

What body paint color to go with

Color is always tough. Is your car stock, lightly modified, or flaired and highly modified? A '77 280Z with stocl bumpers, 14" wheels and factory hubcaps will look very different than a lowered small bumper car with wide wheels and tires and a spoiler. If you have ZG flairs, then you might want to go with a different color on the flairs than the body. IMO, stock colors look better on stock cars, while modified cars tend to accept different colors very well. I don't particularly like black unless you have an original '78 Black Pearl.

-

Frankenstien Engine for Junk Car race

Find some SU's. The car will be slow with a stock engine, but that doesn't mean that it's a lost cause. I built a ~200 hp engine that looked essentially stock and I did it on a budget. I started with a ZX F54 engine and then shaved the head, tweaked the chain guides and modified the cam gear to get the timing right with the shorter crank-to-cam distance. Nobody will ever measure the head thickness or care even if they did. Add a cam and you will have the basis for a decent power gain. Again, there are so few Datsun endurance racers, nobody would have a clue what the cam specs even are. You can run the stock exhaust manifold if you must, or you can pick up a rusty old used header. Another invisible mod that's not expensive is a lightened stock flywheel. Top End Performance used to and likely still does lighten your flywheel. These simple mods along with some fine tuning of the cars and ignition will get your car some much-needed power.

-

Purpose of bracket in front of gas tank to right side

On my race car, I made a drop bracket for the Facet fuel pump so it would prime better when hot. That pump just moved the fuel into the swirl tank where another pump fed the engine. The drop bracket really helped on hot restarts after fuel stops.

-

Rockauto Magnet

I've still never gotten a Z magnet. I have a whole fridge full of other RA magnets.

-

Florida Members Roll Call

Glad to hear. Carl should be pretty safe then too. It looks like Naples and Ft. Myers got the worst of it.

-

Anybody's Z have an "interesting" history?

Not sure how interesting it is, but one of my old Z's was a '72 that I had to sell back in 2003 when I was moving. The new owner had it a few years and put a lot of money into it before he was forced by his wife to sell it. The next buyer got a job transfer to France and he took the Z with him to Paris. I lost track of him a while back, but it was cool to see my old Z with European plates in his yard. @Lazeum was a member here, but I'm not sure if he still has the car or is active on this site.

-

Florida Members Roll Call

Carl is in Clearwater, not too far North of where the eye came ashore. Hopefully all is well.

-

Time to replace the rear suspension bushings in the 260Z

I'd still install the RT to get rid of the useless leather strap. It will keep your OE mount from ripping.

-

Time to replace the rear suspension bushings in the 260Z

Did you replace the front diff mount? They are usually ripped. The RT mount along with a new OE mount makes a nice combo.

-

Time to replace the rear suspension bushings in the 260Z

Those inners look worse than the last three sets I've swapped out. Mine were all the original shapes, but just old looking.

-

Time to replace the rear suspension bushings in the 260Z

You are correct sir. The bushing tool (I won't call it a puller) was supposed to push on the outer shell, but the sleeves are so thin, that it proved hard to do with the socket I used as a pusher. The first side came out that way, but it slipped a bunch of times and I'd have to square it back up. For the next one, I tried a smaller socket that just pushed on the center sleeve. I thought it would tear the rubber, but instead, the bushings slid right out. Had I turned a press tool with non-radiused edges, it would be able to catch the thin outer shell better. Overall, I got the bushings out with no damage while still on the car and it took less than an hour for all four. My pics are on another computer, so I'll update the thread later with the pics.

-

Time to replace the rear suspension bushings in the 260Z

I made an attachment for my spindle pin puller to pull the outer bushings with the arms still on the car. Supporting the arms in a press is a tricky job and if not done properly, it's easy to bend the arms. Pulling them is much easier!

-

Time to replace the rear suspension bushings in the 260Z

The rear bushings aren't that bad other than the outers. You will need to get the old mustache bar bushings out. Fire is messy, but works. Good luck!

-

Harmonic Balancer Broken

I've never had a ZX, but wouldn't the bolt-on pulley be for power steering and the middle one be for A/C since the A/C sheave is the same for S30 and S130?

-

Dropping Overnight Fuel Pressure

Did you also replace the cold start injector? If not, that could be the source of the pressure loss.

-

Is this the shining knight to conquer the dreaded spindle pin?

Same error here. Screen goes red and I get the Unknown Server Error. I took what others did on their pullers and tried to engineer a better version. I used 1" acme thread rod with a thrust bearing. I had an old corner module that looked like it came from the Titanic sitting in my garage for years and I finally tried my puller on it when I moved to AZ. I thought the pin must have been broken. It pulled it right out. I've had others that put up a fight, but still came out. I have tried heat in the past and it never helped with pin removal. I think quite a bit of the pin trouble is from galling at the wedge pin rather than simply corrosion between the pin and the knuckle. Heat won't fix a boogered pin.

-

Is this the shining knight to conquer the dreaded spindle pin?

My home made puller has made even the stubborn ones pretty easy to pull. I've pulled quite a few with it and I've loaned it out for others to use. Someday, I will add a few minor upgrades to it, but it works well. I also made an accessory for it so it will pull out the outer bushings from the control arms. For some reason, I can't upload pics right now. I keep getting server errors.

-

Designing A/C System Using Other Cars Parts?

Once you guys figure all this out, let me know. Now that I live in AZ, I have to put A/C back in my '78. I have all the original parts and a few spare compressors, but I'm not sure if any of it is worth using. It was all removed over 30 years ago. Once the temps are lower in my garage, I plan to work on my Z again. This time of year, my garage never drops below 100F.

-

Parts for Sale: 240Z Parts Collection - FREE

Sounds like when I moved from MI to AZ last year. I had only a few weeks to get rid of 40 years of Z part hoarding. I basically gave away truckloads of stuff. What people didn't get before I left went into a dumpster. I looked at it as paying it forward. Hopefully, many of the parts will find their way onto other cars. The OP in this thread sounds like he or she is in a similar situation.

-

Dunlop Direzza ZIII or Toyo Proxes R1R

I like it! I think the 45 aspect ratio tires look better and should fit better than the 50 series. Mine rub a bit still in the front, but I trimmed and rolled the rear quarters to fit the tires. Mine is lowered about 1" using Tokico springs.

-

Dunlop Direzza ZIII or Toyo Proxes R1R

Can you post a few pics on the car? I'm curious to see how they look compared to the 225/50R16. That's what I run and I want to drop to 225/45R16 the next time I buy tires.

-

Best transmission fluid!?

MT-90 is the best I've ever found for the Datsun trans.