Everything posted by Jeff G 78

-

Speedometer Cable O-Ring Size?

I found something close at the local True Value Hardware today. It is SAE and measures 3/4" ID (19.05mm) x 15/16" OD (24mm) OD x 3/32 (2.4mm) cross section. I figure it was worth $0.79 even if it only works for a while. The manufacturer's assortment box had no information about the material properties, so it's likely nitrile rubber and not Viton. It will buy me time until I get a real one from Nissan or ZCD. Thanks all! Now I need to fit my MSA exhaust to my AZC 6 into 1 header. I know it won't be a direct fit to the AZC header and I want to include a SS flex pipe and probably a resonator as well, so some fabrication will be needed. Hopefully I can get the oval muffler to fit better than the same system on my old late 260 race car.

-

Speedometer Cable O-Ring Size?

Thanks! That's exactly what I was looking for. It doesn't look like the local hardware store or HD/Lowe's have the right one. Amazon has it in a 50 pack in the right material or in some of the big variety kits, but I'll end up spending $20. I guess I'll just order through zcardepot.

-

Speedometer Cable O-Ring Size?

My speedometer cable o-ring must have finally failed after 44 years and my car is leaking trans fluid. Does anybody know the actual diameter and cross section of the o-ring? I could buy one from Z Car Depot, but I'd rather not pay a bunch of shipping and wait weeks for a $3 part if I can find the same o-ring at the local hardware store. Of course I gave away four transmissions before I moved to AZ last year and they all had the mounts and o-rings attached. Story of my life. 🙂

-

Who's running the Panasport 16X7 +11 wheels from ZCar Garage?

205/60R15 are very short, so they will give you a lot more clearance than a 205/55R16.

-

Who's running the Panasport 16X7 +11 wheels from ZCar Garage?

215 is an odd size. Most run 205/55R16 for a good fit. 225/45R16 is another option as they are shorter so it buys some clearance and gives you some gear ratio advantage.

-

Clutch slave cylinder

Same as Zed. I've gotten many bad ones and now I always disassemble them before installation to make sure they don't have any pitting from corrosion. There is no point in installing a freshly remanufactured slave with any pitting. It will leak and chew up the new seals immediately. If the bore looks good on my old failed slave, I just buy the rebuild kit from Rockauto (if they still offer) for a few bucks. I've brought back some nasty looking slaves and brake calipers with a Scotchbrite pad and brake clean.

-

Who's running the Panasport 16X7 +11 wheels from ZCar Garage?

You will be able to go with a higher positive offset wheel with coilovers. For a 16x7 wheel and a 225/50R16 tire, the ideal offset is around +10mm to clear the stock strut and fender lip with little to no trimming. With coilovers, you can likely go closer to +20mm on a 16x7 wheel and 225/50R16 tire though I have not measured the exact differences myself. Of course that combo would look goofy as the tires would be sucked in narrower. With a higher positive offset wheel, you can now go with a wider tire and still fit within the fender. I know a 245 width tire will fit with coilovers and the right offset. I'm guessing that a 245/40R16 tire on a 16x8 wheel would probably require around a +10mm to +15mm offset to clear the strut and fender with similar trimming to what I did. The front gets a bit trickier as a wider tire is more likely to contact things while turned. There used to be a great website for comparing different wheel offsets and tire sizes at www.rimsntires.com, but it is down. I'm not sure if it's gone for good, but it says down for redesign. Hopefully it comes back as it was my favorite site for playing with these things. Hope this helped.

-

Who's running the Panasport 16X7 +11 wheels from ZCar Garage?

Yes, they did. I really like the color.

-

Who's running the Panasport 16X7 +11 wheels from ZCar Garage?

Steve, There is a thread from about 15 years ago where I documented what it took to make my wheel/tire package fit. I can't find it, but here is another thread where I posted pics of the trimmed lips. I believe I removed between 8 and 10mm from the weld flanges between 11 and 1 o'clock on the fender. My wheels are Panasport 16x7 zero offset with 225/50R16 Hankook RS-2 tires. My car is lowered 1" via KYB springs. The front tires rub the front valence when backing up and turning, but not while going forward. An aftermarket airdam will usually give you more turning clearance. The rears took quite a bit of rolling and trimming to clear. I attempted to run them without trimming and the tires were getting cut badly with any moderate suspension travel. I tried rolling first, but it wasn't enough, so I then did it right and trimmed. As I've said over and over and I'll say it again here - ride height has no effect on tire clearance. Lowering a car only changes the starting point of travel. The tire will still move through the same arc regardless of the starting point. If you go with extremely stiff race springs, you might get away with less clearance, but any street springs will still allow full suspension travel over bumps and undulations in the road. That's why the only correct way to check clearance is to remove the springs and run the suspension through full travel using a floor jack under the control arm. Go at least far enough to compress the jounce bumper by 1/3 of its height.

-

Replacement Gas Tank from S30.World has arrived.

FYI, there are no pics in your post.

-

Putting in a replacement L-28

Yes, go LED. I'd also replace all the vacuum hoses while it's apart. If you can swing the money, update everything to Speedhut gauges that actually work properly. The Datsun speedo is always off and the tach was bouncy in every Z I've had .

-

78 4” speaker suggestions

One nice thing about the 78's raised wood floor is that there is lots of room to stash stereo components. I have several amps and a crossover mounted under my floor. I have an Alpine head unit and Polk 4" speakers in the stock locations in the panels fore of the rear wheel arches. I installed all this about 10 years ago, but I never did build a speaker box for the rear speakers, so I have lots of power, but no big speakers to drive. Someday along with the other 50 projects that the Z needs done.

-

Wheel sizing

Okay, let's try this again. The car has a 4x114.3mm STUD pattern. Are the wheels you found a 4x100mm HOLE pattern? If so and they are a +25mm offset, then you could try to find a set of bolt-on spacers that convert from 4x100 to 4x114.3. Most of them are 40mm though which would push the wheels out way too far. You will spend more for those wheels plus spacers than if you simply find the right wheels. +25mm offset wheels always look funny on a Z even when spaced out properly. You need the deep dish look IMHO.

-

Dumb dumb dummy!

- Dumb dumb dummy!

Before I had a floppy drive, I would spend hours and hours typing programs in for games from magazines. With no dri e, I would play the games for a few hours and then shut the computer off and lose it all. Fun times!- Dumb dumb dummy!

I had a Merlin! I loved that game. My first computer was an Atari 800 back in about 1980. I had a modem for accessing bulletin boards at a whopping 300 baud. More often than not, I'd get some sort of phone static and lose the connection before actually finishing any downloads.- [2022] What Did You Do To/with Your Z Today?

Happy New Year Guy! You have been pretty quiet for several years now. I haven't read any posts from you telling us you started a new 240Z restoration. I know you told us that you were done, but none of us believed you then or now. So come on, what do you have cooking? 🤣- Old photos

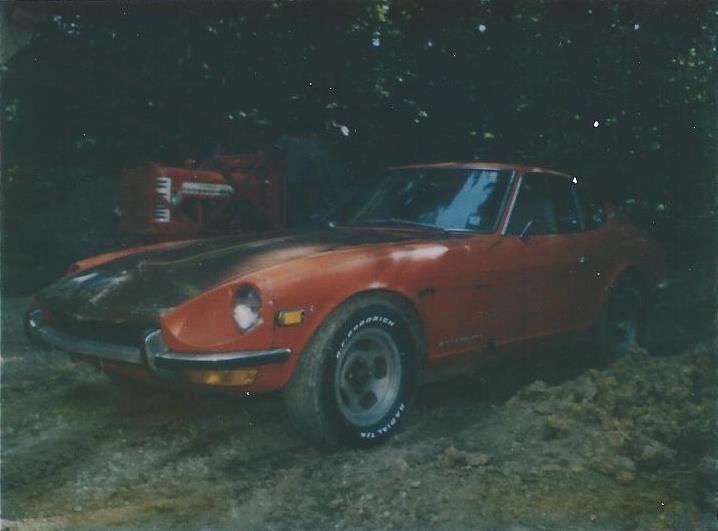

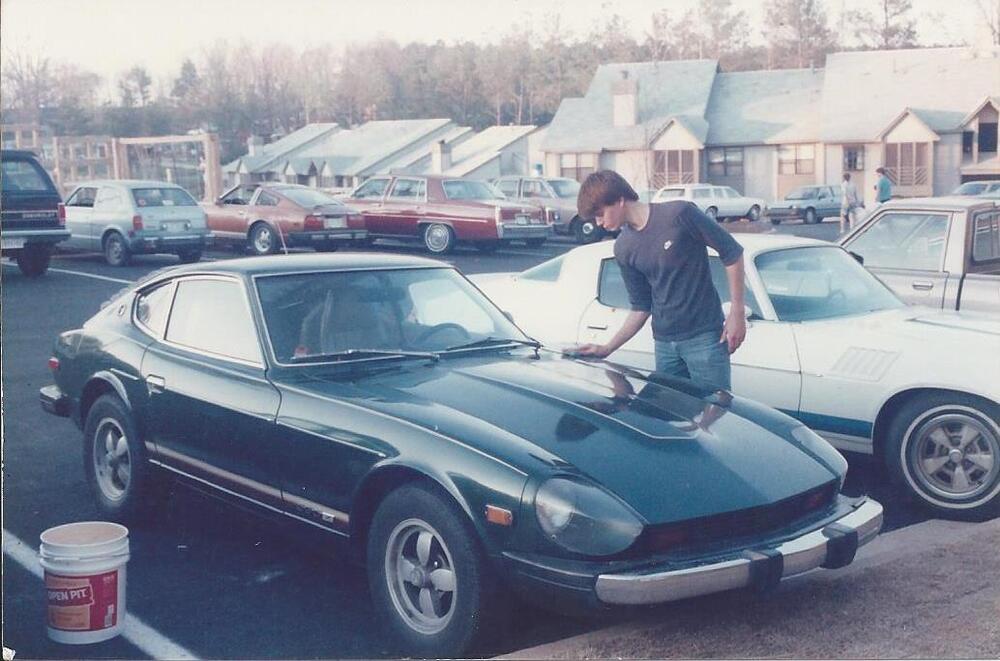

Here are a few of my old pics. First is the orange '72 240Z the day I bought it. It was my first Z and I bought it for $200 along with brown '76 280Z for $400 in 1982. The 240 ran great, but was too rusty to fix, so I parted it out and used the SU's on my race car over 15 years after I pulled them from the 240Z. Next up was my first nice Z. I bought the '76 280Z in Atlanta in 1986. This pic was the day I bought it. I gave it a wash before driving it 750 miles home the next day. I pulled the Libre wheels and sold those to a member here a few years ago and I pulled the headlight covers and after 30 years of storage, installed them on the race car. The white 240Z's were a clean Arizona '72 rolling chassis that I bought sight unseen from Arizona and had shipped back to Michigan. The pic was taken the day it arrived in 1995. The '73 was a really rusty car that I bought cheap because it had a lot of good performance parts including triple Webers and Bilstein struts. I combined the two Z's and cut up the '73. The '72 ended up with a forum member and was moved to Paris, France. Finally, here is a pic of my '78 280Z the day I bought it in Atlanta in 1990. I still have it almost 32 years later.- Who's running the Panasport 16X7 +11 wheels from ZCar Garage?

Probably not, but there are too many variables. Body variation and tire choice will make a huge difference. The same size tire in two different brands and/or models could be shaped very differently. Some are wider than nominal and others are narrower than nominal. Some have very square shoulders and others are more trapezoidal. Also, I say this every time it comes up. Ride height doesn't matter! The suspension goes through the same motion no matter where it starts. A lowered car just starts at a different spot in the travel. A stock height car will likely be on softer springs while a lowered car will likely be on stiffer springs, but both will take the same path. The only way to really check clearance is to remove the springs and run the suspension through full motion using a floor jack under the control arm. Unless the tires clear through full travel with the springs removed, they will rub and could either cut a sidewall or damage the fender.- Pulling My Engine, Need Second Opinion

I posted a thread on here somewhere. Search my name and spindle pin puller and you should find it. If not, I'm happy to send pics. I had access to a lathe which made it easier for sure. I bought a 3 foot length of 1" acme threaded rod, three mating nuts and three washers. I then bought a length of 1" black steel pipe. I cut the rod and drilled and tapped a M12x1.25 hole in each end. I then cut the pipe and welded the washer to one end to support the thrust bearing. One thing I didn't do that needs to be added is to either machine two flats on one end of the rod or drill a hole through the rod. As it is, it works great, but once pulled, the spindle pin and rod are locked together. The pin wedged in the rod as it's pulled. The flats or hole in the rod would allow the rod to be held from rotating. I double nut the free end of the spindle pin to back it off the rod. Without the flats or hole, I have to put the rod between blocks of wood in a vice and even then, it can be hard to hold.- Pulling My Engine, Need Second Opinion

Yeah, the washers put all the stress on the threads. The pullers lock the pin to the puller and the puller takes all the abuse. I made my own using acme threads and a S30 front strut top bearing and it works great.- Pulling My Engine, Need Second Opinion

Not quite yet. The Badge isn't awarded until spindle pins are pulled.- Pulling My Engine, Need Second Opinion

Looks good. The extra strap can be around the same runners. You will need to tip the rear way down, so make sure your straps give you plenty of adjustment room. The front should be as short as possible so you have enough lift.- Pulling My Engine, Need Second Opinion

I'm guessing the engine will roll a bit to the left when you start to lift. The front strap is on the right and the left strap that should be on the left is now centered, so the forces will be off center. I've lifted many with broken rear studs and I believe I wrapped the strap around the rear runner of the exhaust manifold. It should still work the way you have it, but just be prepared for the engine to roll a bit. Also, be very careful about the straps pulling on anything that could chaffe or cut them. The last thing you want is a 600 lb engine freefalling! That would be a very bad day. I usually use two sets of straps just to be safe.- Alternate OEM door mirrors?

It looks really good. I ended up finding an OE LH mirror and I lucked out. It just barely sticks out wider than the widest part of the body, so my car still fits through my 69" wide golf cart door. I guess I'll weld up the holes in the RH door and just stick with the OE mirror now. - Dumb dumb dummy!

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.