Everything posted by EScanlon

-

clock

Da Flash: Re-read this post and you will note a bunch of references as to where and how to oil the clock mechanism. As far as the hands and faceplate, I found it much easier to remove them than to worry about bending or staining the plate/hands while working on it. Good Luck Enrique

-

need a rear trasnverse link

Beandip's computer is down right now, but I spoke to him earlier today. He SHOULD have the curved one, he DOES have the straight one. Go figure. Enrique

-

Preping, painting and attaching BRE front spoiler

Painting Fibreglass is basically the same as painting sheet metal except for ONE item. That is the use of a SEALER. Whether Sealer alone or Sealer/ Primer. The Sealer ensures that the fiberglass resin is sealed and does not continue to "bleed" causing problems with the paint. Enrique

-

Colour Schemes

Use the same color as on Axelr8's avatar. That's the new 350Z Metallic Orange color, don't know the "proper" name. Enrique

-

Hood hinges, what color

All were Body Color when they left the facttory. Enrique

-

Need New Auto Shifter Handle for 73 240zZ

They are interchangeable if I recall correctly, however, the later years had a CHROME handle with a colored vinyl insert and a black button. (The buttons were identical, although I seem to recall seeing some in blue). The earlier were plastic. Personally I like the looks of the later shifter better, but I just used the original. Enrique

-

PDX Auto Show Meet for PDX area Z Owners

I'm sending this message via PM and EM to as many folks as I can think of that reside in the Portland Oregon; Vancouver Washington area. The NW-Z club is planning an informal meet at the Portland International Auto Show on Saturday, February 7. We will meet at 5:00 PM at the Nissan display, next to the 350Z. You may want to arrive a little bit earlier, as the admissions lines tend to get a bit long on Saturday. For more information go to http://www.paragonexpo.com/portland/ Although I am not a member of the club, I am posting this for all SW Washington & NW Oregon members of this forum in the hopes that we can meet up there. Gary (Beandip) and I will be meeting there a bit early; 3:30pm to first view part of the show and then meet with the other members of NW-Z. Enrique

-

What defines a 240Z a classic?

Then I have misunderstood the question. You did not ask what makes me fond of the Z, you asked what makes the Z something to be fond of. My personal definition would not entail the term Classic. That is not why I wanted one, nor why I bought it, nor why I have done so much work on her. That she is considered a classic by others, to me just means that others find her to be desireable. Just like dating a gorgeous tall model. While some guys would desire the car for the prestige of owning one, just as in dating a model. Others would rather enjoy the thrill of having her company. There is just something about my Z that has always appealed to me and given me pleasure. And like dating a model, a gentleman never discusses what pleasures he shares with his lady. Enrique

-

center console

Billcapp: That is the EARLY 71 Center Console. Enrique

-

What defines a 240Z a classic?

The definition of a classic is similar to what one of the Supreme Court Justices said regarding pornography, paraphrazing as I don't have the original quote: "I can't give you a definition of what constitutes porn, but I know it when I see it." There are hundreds of vehicles that came out in the late 60's, 70's and early 80's that will be considered old, and maybe qualify for a license plate that denotes them as being older than 24 years. But they would never be considered Classics. Now, I know that some of them would elicit pangs of remembrance and even a desire to sit in it, but not the yearning to drive it and enjoy it again that a true classic evokes. Consider: The Pacer The Hornet The Pinto The Chevette The Fiesta The Citation The "K" cars The Fairmont As the years go by, some of these will gain collectability as their numbers go down, and seeing one is a visual treat. Yet, you still don't purposely go out to find one of them until many more years have gone by. Then you buy it just because it's an antique. Some people would then call them "Classics". I think I'll just enjoy my Z and let others determine whether they think mine is a classic. Enrique

-

Which one you like better?

The top car definitely needs something in front so it doesn't appear to be popping an eternal jump start. Or you can lower the front end. The bottom car definitely needs to lose the whale tail. See if you can find something that isn't so drastic. A spoiler wouldn't look bad, but just needs to blend into the body lines better. You're also thinking of blacking out the chrome around the windows. If you do so, consider either black anodize on the bumpers or go with the shortened front in fibreglass and the back molded into the body. Enrique

-

Do Headlight Covers get Fogged Up?

DO NOT USE RAIN-X INTERIOR FOG! I used some in my Acura, and the only way I finally got it off the windshield was to have the windshield replaced. Don't try to drive into the sun with this stuff on, you will NOT see through the windshield. All you are going to wipe on is a horrendous snot film. It smudges and catches dirt and dust, God forbit you smoke in the car. Using it for Headlight covers? I would stick with their original Rain-X formula for EXTERIOR surfaces (YELLOW BOTTLE). Regarding the 280, it is very possible that by then they added a splash pan underneath the headlight scoop. In the 240's that is not the case. It is a PITA to get up there to work those things. Enrique

-

Do Headlight Covers get Fogged Up?

The main reason that your headlights are getting fogged up is that the area around the headlight bulb itself is open. There is no splash guard around the bulb lens to the "scoop" portion of the headlight opening. As you drive along the mist from the front tire splashes in front of the tire which then gets sucked up to the front part of the fender and hence into your headlight scoops. Add that your headlight cover has a couple of drain holes and you are causing a small vacuum INSIDE the headlight scoop area. This further sucks in the water. How can you fix this? Look closely from underneath the car, just in front of the front fender support where the headlight scoop attaches to the fender. Have someone shine a flashlight around the headlight bulb and you'll see the light! (no pun intended, but what the hell.) You could seal this with duct tape, but be careful as you don't want to inadvertently affect the position of the headlight bulb in relation to the car's general axis. You'll end up with misaligned headlights (Vern, there's a squirrel in that thar tree!). Also, make sure you don't make it impossible to access the alignment screws, should you bump it a bit. The other way is to either get some foam tape around the opening. Problem with this method is that there isn't much to stick it to. I reduced the problem I had with this by wrapping a 2" wide piece of squeege blade rubber (check with a window washer, that's where I got mine.), that in turn is zip tied around the tube of the headlight scoop, so that there is about 7/8" protruding past the tube of the scoop. Look closely and you'll note that when you mate the scoop back to the front fender / headlight assembly, it just barely touches against AND around the complete headlight bulb / ring assembly and gets very close or if possible touches the inner fender support. You CANNOT seal it to be pressure proof, so the best you can do is to limit the amount of air to be pushed through it. By sealing the back you eliminate the major source of air. The very front portion of the cover is the only spot you should need a drain hole. Typically this is at the seam between the two ends of it, but it shouldn't be a requirement now. If you do leave a small gap, realize that air and water can get pressured into it by the force of the air against the front of the car. With the OEM covers, there IS a hole in the gasketing around the cover. The difference with those headlight covers and the standard ones you can get from VB & MSA is that the OEM's actually fit on the OUTSIDE edge/lip of the sugarscoop. The aftermarket ones are expected to rest INSIDE the edge of the sugarscoop. That's why they have an edge gasket. Personally, I would not leave a gap, and WOULD seal the back portion as best as I could. 2¢ Enrique

-

Looks like Mikey is Buying another 240Z!

Actually Mike is buying it so he can restore it. With all the combined knowledge about the engine, suspension, paint and bodywork available here it is actually an advertising campaing in the works. He'll post the picture as shown on the auction and then show the AFTER shot. When people ask how he did it, he'll tell them that it was due to the help of the club. THEN he'll start charging the new guys $15 a pop and.......SHHHHHH :dead:

-

Z Mags

The Hub was a generic hub from your local wheel dealer. In my case Les Schwab. I say generic because it will work for 4 and 5 bolt wheels. The key was to get the hub to fit through the hole in the wheel. The "spinner" part of the knock off was also bought at Schwab, but they are Coyote brand spinners. They had them in 2 "wing" and 3 "wing" models in both anodized black and chrome. The Center Cap Logo was also obtained off e-Bay.

-

Wheel well trim Front

I bought both the front and rear set from MSA. They fit quite well, and although a bit of forming will make it better, I can't argue with the design. If I recall they were about $40 per set.

-

Fully Lit!

Sadly that is the donor car. She has graciously donated her dash, seat reclining mechanisms, and a few other parts in order to make Z-Oro the car she is now. The donor car, is a terminal case. She has major MAJOR rust. I would be afraid to ride in it if it were to be pulled with a chain. Enrique

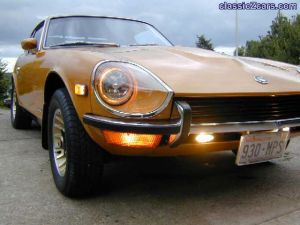

- Looking Back at Ya!

- LF_Cover_Lit

- RF Corner

- Wink!

-

Fully Lit!

-

Center Console

The red switch is the current switch for the fog lamps, however, thanks to Kats and Alan, I was able to get the proper switch for that panel, which is a Parking Lamp Switch. That switch operates additional bulbs in the front and rear but only on ONE side at a time (not blinking). This is to highlight your vehicle when parked on an unlit road. (Japanese Market Requirement)

-

Dash

Also, if you'll note, there are 2 Cigar Lighters. That's because the center console is a Series I (as we refer to it in the USA), and the dash is from a 72. Since I plan on adding the fog light switch later, I filled it in with the lighter instead of a gaping hole.

-

Dash

The "fuzzy dash" is NOT the way I run the car, just when I expect the dash to be exposed to the sunlight. As expensive and difficult to find good dashes is, I'll be darned if a bit of vanity is going to make me get a new dash sooner than I need to.