Everything posted by 2ManyZs

-

Konig Rewinds

Well, I don't know for sure if they still have them, but their web-site still shows them available... but, you never know until you order if they are still available. Go to http://www.nismoparts.com/ then click on catalog, then put in part number 62300-N3000 and you'll see the price.. :classic: You might also check with MidwestZ to see if she has a supplier as well, and you'll get a discount to boot...:cheeky:

-

Short shifter for T-5

Should be able to find them from Jegs or Summit Racing for Mustangs or Camaro's.... not sure if they would have the right bend in them though to clear in a Z....

-

Konig Rewinds

I don't think they look bad... although, I prefer the look of Panasports....or maybe it's just the color of the car that makes them less than perfect... I just get a kick out of people's descriptions on Ebay... Mesh grill rare and expensive? Not... N42 rare and expensive? Not.....

-

Alternator, Condenser, Ideas?

Could be just a loose wire cutting it out. Check all the connections from the distributor to the coil. Could be a wire is corroded and partially broken as well.... I've found many wires on a couple cars that were so hard that you couldn't bend them and then they just snap when you try to bend them. If not there, since the tach is going dead, it could also be a problem in the ignition switch or wiring to or from it as well.....

-

Ford 9" Rear End

It's been done before. The main problem is all the chassis reinforcement that has to be done to mount the locating links as the unibody wasn't designed to be used as a suspension mounting point that locates the rear end. You end up almost having to rebuild the entire rear clip to locate the rear, which in the long run would probably end up adding a significant amount of weight. Hot Rod magazine did a 240 many years ago with a 9" rear and a V-8. I've still got the magazine around here somewhere.... maybe I can dig it up and scan the pics of the work they did to mount the rear.

-

Are These In Good Condition???

Picture doesn't show the faces of the ring gear very clearly, but it doesn't look to be galled. Spider gears have some wear but that isn't the most important part. Looks pretty good to me...

-

Toyota 4 piston caliper brake upgrade

Uh... you might want to re-think your parameters for your discount... besides you and I there are only 3 other members over 1K posts.....:stupid: :devious:

-

2 240z's which one to keep?

Should be an easy choice... always choose the chassis with less rust, unless the rust on one car is only on the outer body panels that can be easily replaced. In your case, I'd keep the yellow one.....

-

Toyota 4 piston caliper brake upgrade

Do 3K posts get me them for half price???? ROFL :cheeky:

-

Air flow meter ground wire

If I remember right, the ground wire is connected to the bottom of the air flow meter body. The air flow meter does need to be grounded, the rubber grommets on the bracket are there to shield the air flow meter from vibration, or I should say the potentiometer needs to be shielded from vibration.. Because they also will not let the air flow meter ground, the wire needs to be connected.

-

Some pics to share..

Ouch.. and I thought my parts car was rusty.... maybe there is hope for mine yet...:cross-eye

-

electrical fire and smoke!

I'm wondering if you don't have a voltage regulator problem that is causing too much voltage...the fan speeding up with the RPM's seems to point in that direction... all your problems could be caused by too high a voltage from the alternator, you should verify your voltage regulator before you do any more driving as if it is what I'm suspicious of, it could result in a battery explosion.:cross-eye

-

Besides the Zcar, what are your favorite cars?

Boy... what a question....:cross-eye If money were no object, and in no particular order... Z32 Convertible Z32TT 67 Roadster Skyline GTR 65 GTO, gotta be six barrel and 4 speed 70 Tran Am, gotta be Ram Air lll or lV Another 73 Cuda, only this time with a crate Hemi and 4 speed Viper GTS or the new "real" convertible Ram RT/S Hemi Superbird or Daytona 79/80 Aston Martin Vantage Volante, gotta be a manual Any of the original AAR Trans Am Cuda's BMW M3 or M5 Gullwing Mercedes Sunbeam Tiger Race cars? EP 240Z 600 Racing Thunder Roadster FFR Cobra Spec Racer Cobra AAR Cuda to race Vintage BSR C-Production 240Z replica 96-99 American Eagle Coach with a three car enclosed trailer behind it?

-

Interesting pics....

I thought that pic looked familiar when I first looked at it...:stupid: Guess I should have known....:devious:

-

rear hatch deck panel wanted

Me thinks these would be a tad closer.....:cross-eye http://www.classiczcars.com/forums/showthread.php?threadid=8068

-

Interesting pics....

-

Interesting pics....

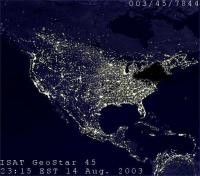

During the big Blackout of 2003.... or maybe a better title would be"Where were you when the lights went out?"

-

280 with a 240

Results using the search box show quite a few threads on the subject... http://www.classiczcars.com/forums/search.php?action=showresults&searchid=60420&sortby=&sortorder=

-

Gearbox Oil - Should I Change?

Easy to do and it's rather inexpensive insurance. Pull the drian plug out of the bottom and drain it, pull the plug on the passengers side to fill it. The hardest part is getting the lube back in it, most times I use a clear neoprene hose and run it from the engine compartment down into the fill hole and re-fill it. The diff is done the same way, as the mustache bar makes it a little difficult to pour directly from the container, pull the drain plug, and re-fill through the top plug. Changing both will cost you in the neighborhood of 25-40 dollars depending on which brand of lube you choose if you switch over to synthetic, even less if you go with non-synthetic lube. If you want some imprevement, go to a synthetic lube such as Red-Line MTL for the tans, and 75-90 for the diff. You'll get a bit slicker shifts and it will last much longer than regular lube. You don't have a filter on the trans or diff to get the contaminants out of the lube like you do an engine, but you still change your engine oil regularly right? So why not change the lube in the trans and diff both and get longer life out of the bearings,synchro's and gears? All the fine metal particles in the diff and trans have no place to go excpet to keep getting dissolved in the lube and spread throught out the case. Once the drain plug magnet builds up to a certian point with shavings, it is no longer going to pull the shavings out of the lube.

-

Availability of Rear Body Panel

Since it's all one panel from the bottom to the inside hatch area, there's no replacement for the section below the lights. Only a couple places have the section inside the hatch. Unless you can find a NOS one from Nissan that has been NLA for years.:disappoin If there's no rust anywhere else, especially inside the hatch, probably a small patch panel is about the only way to go.

-

New MSA parts

Can ya put me down in your will for the Roadster? Got enough parts... just need a couple more driveable cars....

-

New MSA parts

Radiator is kinda high priced when you can buy one from Summit for 300 or so... But, the fuse box is gonna sell like crazy even at 200 bucks a shot...:tapemouth Makes me wish I had made it.....

-

Will a 71 rear bumper fit a 73?

It will work fine, the only thing is you would want to use the early mounts to mount the bumper closer to the body. They aren't too hard to find, you might even get lucky and find brand new ones yet from some of the major suppliers. The main difference in the bumpers themselves is the mounts, and where the upright "bumper guards" are mounted. The early cars are mounted further apart than the later cars. The 73's use a rubber "filler" between the bumper and the body as the mounts they used mounted the bumper further away from the body.

-

Series 1 FS EBAY

Air cleaner is correct, it's the early cars that have the winter/summer manual control. The door lock is kinda odd, but in a way it is a good idea:ermm: The only thing that I'd be skeptical of is the gas tank with pinholes... sounds like it either needs a whole new tank, or maybe it's just the vent lines that are leaking....:stupid: The interior looks pretty orginal except for the stereo, but the fading of the door panels say it is orginal. Looks like this car would need a lot of work on the interior, but after that it would be pretty nice. It says it is re-painted the original color, yet underhood is black... wonder what's up with that? One small item, it has the later black wiper arms... but they don't diminish the value since they are easily changed.

-

Will start, won't run!!!!

Still running the stock FI? If so, first thing I would check is the AFM and see if the flap is working correctly. While you are turning the motor over, check to see if the injectors are firing by placing a long screwdriver on the metal hold down ring and place your ear on it for a "stethoscope". No noise? Electrical problem possibly tied to the wiring around the distributor. Just and FIY, you ought to get rid of the mechanical pump if the electric one is operating OK. No need for both on a FI car anyways. If the electric goes bad, the mechanical would have a hard time pulling fuel through the non-operating electric. I'd say if it was runnning before you pulled the distributor, you might not have a wire secure somewhere and the injectors may not be firing correctly.