Everything posted by CanTechZ

-

1970 HLS30-06521 Re-Restoration

When pollution controls are removed most people don't go to the effort of sourcing and replacing the two groove pulley and E46 balance tube that has extra ports and brackets for the emissions controls. Here is a picture of my "UN" set up with the single groove pulley and E41 balance tube, sometimes called "euro style". These items may be easier to spot in your resto pictures.

- 1970 HLS30-06521 Re-Restoration

- 1970 HLS30-06521 Re-Restoration

-

What's the most needed Z part that's currently NLA?

Check with @nix240z He makes these... https://www.240zrubberparts.com/apps/webstore/products/show/4432194

-

1970 HLS30-06521 Re-Restoration

@Namerow Thanks I am lucky that this area is in good shape, I'm definitely not so lucky in some other areas. I thought the foam cowl pads were there from the start, there is a TSB from Mar/71 that adds welded in supports to correct the issue with the flexing of the cowl cover. Your theory about when the wiper motor cover bag was introduced does make sense. @grannyknot Not much info out there regarding the type of cover that I have. When I searched I did find that @240dkw has one on his 7/70 car. Both are Canadian cars that are very close in vin.

-

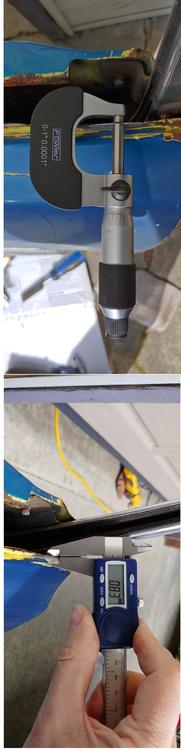

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Here are measurements for both doors and from a LH door from my 12'70 parts car. All measurements are bare metal taken from the top window edge with the chrome strip removed. The door handle openings are too small to measure through. 7/70 LH door vin 06521 measurement by micrometer: .031" (.79mm) by digital caliper: .80mm 7/70 RH door vin 06521 measurement by micrometer: .033" (.84mm) by digital caliper: .84mm 12/70 LH door vin 16531 measurement by micrometer: .033" (.84mm) by digital caliper: .83mm Sorry, I don't know how to rotate images when uploading, they look correct on my computer. Also regarding measuring, I prefer to use a micrometer when possible as it is more precise. When measuring with a digital or vernier caliper I find it best to only use the end of the jaws for measuring sheet metal, when using the full length of the jaws flatness of the sheet metal can effect the measurement. Also I find it's much harder with a caliper to get a true reading while taking a picture.

-

1970 HLS30-06521 Re-Restoration

This weekend I also pulled off the cowl cover to remove the wiper motor assembly and inspect heater fan intake duct and surrounding sheet metal. I'm happy to report that I don't have a rust issue in this area. Here is a good discussion, with fixes, on this subject: Here are some pictures of what I found, I was surprised to see that, except for over spray, the wiper motor cover was fully intact and that the grommet was also in very good condition. I also took some time and cleaned up the wiper motor cover. Before and after pictures attached. Anyone know when the change to a bag for the cover happened?

-

1970 HLS30-06521 Re-Restoration

Started stripping my doors, removed the door panels and chrome weather strips. Wick Humbles book was very useful, with his tips and the right tools I did no damage to the fragile door panels and chrome plastic covers on the passenger side grab handle. The passenger side still had the plastic film vapor barrier fully intact and even after removal is re useable.

-

What's the most needed Z part that's currently NLA?

Replaced that diff mount on my 1970 in 1998 and still have the old part. I have contacts in eastern Europe that produces rubber and rubber backed steel parts. When I get time, I will try to make a drawing off my old parts and look into making these. I paid $37.44 in 1998, it will be hard to meet that price.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

I removed the chrome trim from my doors and found a spot to measure the door skin thickness. I measured .036" (.91mm) with paint, and .032" (.81mm) with paint removed.

-

1970 HLS30-06521 Re-Restoration

Just getting back into the disassembly of my car after delay due to a few life obstacles. Back in late November I removed the exhaust from the resonator back. Last week removed the seats and seatbelts. I will hopefully be posting more regularly, as I'm wanting to get the shell to the body shop sooner than later. Cheers, Mike

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

@Namerow When I strip my doors I will try to get measurements, I also have doors from a 12/70 parts car in my shed that I will try to get to and measure. @ConVerTT I respect your position and look forward to seeing your findings, thanks in advance.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

You make valid points, when I removed paint for the previous floor pan measurement I did my best to not remove any metal. I decided to re-measured my front fenders and rear quarters. This time I used a micrometer and took all measurements thru the opening for the side marker light openings. First here is a bit of history on my car, the LH rear quarter was replaced in 1979 with an OEM original part number 78101-E4600 (correct for up to 12/70) and was painted 918 during that repair. In 1982 I replaced the RH quarter panel and both front fenders and then had the whole car repainted in a GM metallic Ontario orange. In 1982 I was still able to get OEM parts from my local dealership but for the RH rear quarter I was only able get p/n 78101-E8800 which applies for 1/71 on, and had a hole for a side vent that I had welded closed as my car is a 7/70. So the LH rear quarter has one more coat of paint than the rest of the car. Here are the new measurements I recorded through the side marker light openings, including paint: LH Front - .041" (1.04mm) RH Front - .040" (1.02mm) LH Rear - .041" (1.04mm) RH Rear - .039" (.99mm) Here is a measurement after carefully removing paint on the LF front. Outside seams to have one top coat, a reddish primer coat and original factory greenish gray primer, the inside seems to have what looks similar plus a black primer? Measuring on bare metal I recorded this: LF Front Bare - .031" (.79mm) I'm now thinking that both the body panels and floor pan were produced using 0.8mm thick steel.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Here is another floor pan measurement, this time for the mid floor section behind the left seat. Measured .030" (.76mm). Most likely 0.8mm thick sheet metal. Again about the only good purpose for a rust hole.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

This morning I re-measured my floor pan thickness with seats out and better light, the new reading was .040" (1.02mm). However with the better light I noticed that there was still original paint on the under side that was quite thick. After scraping off some paint I measured again and the new reading was .0315" which equals .800mm. My car is a 7-70 production date.

-

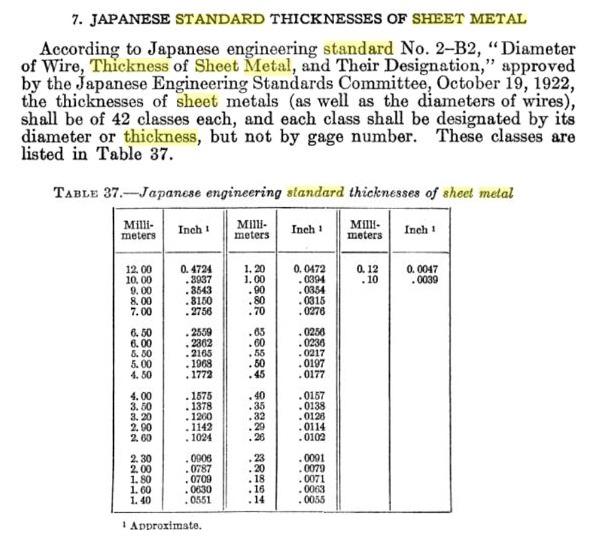

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Yes, I was also happy to find that table with available standard thicknesses from the period. With enough volume and modern methods manufacturers today definitely have more options. I plan to remove my seats on the long weekend so I will have better access to measure again. I will report back with my findings.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Here are a few references regarding Japanese cold finished sheet steel thicknesses and tolerances. JFE CR Steel Sheet [Japan].pdf

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

I did my best to take the measurement where it was clean bare metal on both sides. Here is a picture from the underside. No sanding has been done, just solvent cleaning after removal of undercoating and the tar mat inside.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Couldn't get it with my vernier but a micrometer worked for the floor pan, to sound metal through a rust hole. The drain holes were not large enough. Measured .044" (1.12mm).

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Using the attachments for my vernier calipers I measured 1.09mm thk for the rear 1/4's and 1.13mm thk for the front fenders (including paint). Obviously the measurements will vary where taken due to thinning of the metal where it is stretched during the pressing process. Just thought it was a good chance to try out my seldom used attachments.

-

Containment

Yes, I'm definitely won't be using that fan belt. Also here is a picture of two 74932-E4100 scuff plates that I have, one is from 1984 and the other from 2016. I found it interesting that the description changed so much. In 1984 it was "PLATE-SCUF" as is in the parts book, the part from 2016 reads "HOOK ASSY-ROPE"

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Firstly, thanks for starting this body metal thickness topic. Interesting a couple of days ago I was looking up some fastener specs and came across some info regarding BW vs Unified threads. It seems that BW system predates unified, In the UK Joseph Whitworth was the first to develop a standardized fastener system. Decades later American William Sellers, building on the work of Whitworth, proposed the another standardized system that became the unified system we use today. His system was cheaper to manufacture, sacrificing some features relating to fatigue performance. Here is an interesting fastener history link: https://www.nord-lock.com/insights/knowledge/2017/the-history-of-the-bolt/

-

Wiring harness routing location

-

April 1st, no fooling.

Definitely an off year for April fools, however a neighboring community sent out this, it didn't go over very well.... https://www.tricitynews.com/news/holy-crap-mixed-reactions-to-port-moody-s-april-fool-s-joke-1.24110569

-

Containment

Not weird at all. Here is a 11720-E4615 Fan belt that I purchased as a spare and have kept in the car since 1979. I even have the invoice.