Everything posted by CanTechZ

-

3D Models of S30 Parts for Discussion and Sharing

Thanks Mike, more to follow as I get time.

-

3D Models of S30 Parts for Discussion and Sharing

If any one is looking for a free solid modeling cad option you might want to check out Onshape. I'm not a user or afilliated but it looks interesting. https://www.onshape.com/ It is a cloud based app so there a no files to install and apparently if can be run on almost any device. It is relatively new but looks to have most features that will get you started to see if 3D cad is right for you. One catch is that all your work is also on the cloud and the free version is limited to 10 files (up to 100MB) being private, but you can also make your work public with unlimited files up to 5GB. The free version is not feature crippled and apparently is exactly the same operationally as the professional version which has a monthly fee and no private file quantity or size restrictions. FWIW Mike

-

3D Models of S30 Parts for Discussion and Sharing

-

3D Models of S30 Parts for Discussion and Sharing

I'm not on FB either, maybe I can ask nicely and get my wife check it out and let me have a look.

-

3D Models of S30 Parts for Discussion and Sharing

While I had the choke assembly disassembled from my 7'70 240z to deal with a sticky choke issue I started to measure and model the parts as an exercise while I had some free time. It got me thinking that others might be doing the same with other parts and might like to share stories and maybe a few cad files or just to show off what you are working on. I am a mechanical designer and use Solid Edge as my primary 3D solid modeling tool, I am also learning Solid Works and have a background with 2D AutoCAD. Here is a sample of the work I have done so far, comments welcomed from cad and non-cad users alike. If we get to the point of sharing cad files I'm wondering if @Mike would consider adding a 2D/3D cad section to our downloads area, if file size is an issue limits could be established. Cheers, Mike

-

That little screw holding the choke lever

I'm actually working on modeling the full choke assembly so I can maybe in the future make some parts to add a hand throttle. We're getting off topic as this thread started with a discussion of "that little screw". I will start a new thread for discussing 3d modeling of S30 parts. Anyway here a couple screen shots of the choke assembly so far:

-

That little screw holding the choke lever

On my 7'70 I recently noticed that the M2 screw for the choke knob that I was using was actually too long, the correct length should be 5mm. Using a 6mm long screw could cause damage to the knob if you over tighten. Here is a drawing showing the issue, and a couple of 3D model images:

- Order of base interior parts

-

The-Chilliwack-Progress-Wed--Sep-13--1972-sm.jpg

From the album: Chilliwack Datsun Newspaper Ads

-

The-Chilliwack-Progress-Wed--Jul-15--1970-crop.jpg

From the album: Chilliwack Datsun Newspaper Ads

-

240Z Resto - 01/1970 Car

My early heat shield is steel and looks to be clear zinc plated, these pictures are from my obviously un-restored engine bay. I did a quick partial clean up of one end to see how much plating is left.

-

Fitting 240Z bumpers and Valences to a 280Z

-

Fitting 240Z bumpers and Valences to a 280Z

You're welcome, no problem getting you dims for the rear as well later today. I work from home so this kind of stuff reminds me to take a break and stretch my legs.

-

Fitting 240Z bumpers and Valences to a 280Z

Here is what I could measure off my front bumper, hope this helps Mike edit, I will try to get measurements for the rear later today.

-

280 Z Non Locking Driver Door

You got me wondering about this. On my 240 I have to use the key to lock the door from the outside. I did some checking about this by reading the various owners manuals found on http://www.xenonzcar.com/s30/ownersmanuals.html and it seems this feature was added for the 1977 280Z. Here are the pages from the 1977 & 1976 owners manuals:

-

Hardway's 1971 240z #8011 - Build and Repair Thread

I remember that thread as well, but I couldn't find it. However I did remember that @nix240z makes them, here's a link to his website: http://www.240zrubberparts.com/apps/webstore/products/show/5696404

-

Engine decoding a series

This useful link has the FSM for the 1975 Datsun B210 which also used the A14 engine: http://datsun510.com/manuals/

-

What's in YOUR garage?

Why get a gator when these are cheaper and have a heater? Luckily I have not had to use "my snow shovel" since Xmas '08 when these pic's were taken. To those of you experiencing this crazy weather, stay safe.

-

pocket in 240z floor pan

Could it be an ergonomics thing. When I step out of the car my toe seems to find that spot as I rotate and balance my weight to exit. Especially when I'm in a tight spot and not able to open the door fully, like my garage.

-

What a Difference a Day Makes with RedBird

My 240 has a copper gasket/washer on the tank plug, I checked the parts book and it calls up a gasket for the 280's as well. Could also be a leak at the fuel level sending unit, I had a bad o-ring on mine that leaked.

-

Intake Manifold Thermostat - How do I check it and service it?

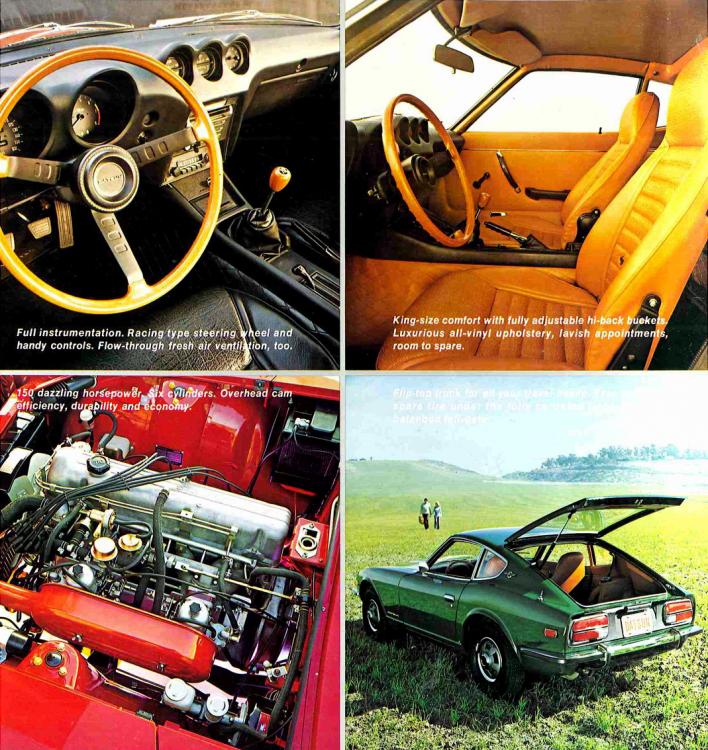

This is a page from a 1970 sales brochure, to me it looks like engine pictured does not have an intake manifold thermostat. By the position of the small hose over the heat shield it does not look like there would be enough room for the thermostat. Pictures I have seen with the thermostat have that small hose extending beyond the heat shield as in the picture below of Jalex's '72. Just my opinion. Mike

-

1975 Mitchell Foreign Car Collision Estimator Guide 240Z-260Z

- 31 downloads

- Version 1.0.0

This is the Datsun 240z - 260Z section of the 1975 Mitchell Manual's Inc. Foreign Car Collision Estimator Guide for Auto Body Shops. includes parts prices and labor hours from circa 1975. The first few pages are a procedure explanation for using the Mitchell Manual.Free -

Intake Manifold Thermostat - How do I check it and service it?

Looking closer at the parts book I noticed that 9/71 was also when three screw SU's were added and it seems that was when cooling passages were added to the base of the carbs. I did a bit of searching here and found this topic: http://www.classiczcars.com/topic/18629-4-screw-sus-and-the-coolant-heated-manifold/ See post 2 by Arne. The investigation continues.....

-

Intake Manifold Thermostat - How do I check it and service it?

I can't be certain that my '70 car never had this part, but I have owned it since 1978 and I did not remove it. To me it seems strange that the manifold heat control thermostat is not mentioned in the 1970 FSM. Also in looking at the parts manual I noticed the pipe manifold that wraps around the back of the engine connected to the hose that connects to the thermostat did change in 09/71 (item 26 on the attached parts book page). On my car the thermostat would not physically fit unless I bent or modified that pipe manifold. I could be wrong but I think the fact that there was no start date in the parts book for the thermostat might indicate it could be backwards compatible if you also change to the newer pipe manifold (p/n 14053-E8800). Just some food for thought. Mike Edit> I missed answering your question about "no-thermostat solution and blocking off the circuit etc." Your logic does seem to make sense, all I can add is that over 38 years of driving my car and not having this thermostat with the coolant path open I have not had any issues. Maybe others with original series one cars will jump in and offer opinions or confirm if this part was in fact originally included on their car. I wonder if anyone has an old parts book from 1970, mine is from 1978. To me it looks a little ambiguous that the item 38 thermostat is offset and parallel to the pipe string and why would item 20 (connector-water) be required when the thermostat case cover can thread directly into the intake manifold? Just curious.

-

Intake Manifold Thermostat - How do I check it and service it?

Lot's of good info here, thanks for sharing this. Was the manifold thermostat first installed on the 1972 model year as that's what it seems to state on page EC-12 of the 1972 FSM. I don't have one on my 1970, and I don't believe there ever was one, also I can't find any mention of it in the 1970 FSM. I see the benefit of having this thermostat, I'm just curious about when it was introduced.