Everything posted by hmsports

-

more Z body kits

From what I understand Arizona Z Car is selling all their body kit molds too - $30K buys it all.

-

Ram air

The stock air cleaner assembly has built in air horns. I've seen aftermarket horns but they are very similar to the same size and shape - just more rounded all the way down. I don't know if you would notice any improvement - it is most likely one of those you could only measure on a high-dollar engine dyno. This of course is just my opinion - I am no expert in air flow dynamics. I use two separate aftermarket air filters in which I have taken a stock backing plate and cut out the air horns and bolted them inside.

-

Rear brake drum stuck.

I got so fed up once with one of mine I took at 12# sledge and cracked it good - popped right off! Now, I wouldn't recommend this - unless you are replacing the drums.

-

Ram air

As long as you don't extend the intake beyond the bodywork and make any new holes in the body or frame, you can get away with it. Always a way to push the limits :classic:

-

Ram air

2Many has a great idea of getting a tube out in front of the radiator to get the coolest air to the carburators. The next thing to keep in mind is that air will tend to find the path of least resistance. This is why most racers build shrouds that force all the air that comes in the grill through the radiator. These are made with thin sheet metal and all the gaps are filled so no air can get by without doing some cooling. It would be a good idea to build a box that 2Many's duct would hook to. The box should have a large opening (say 12" tall by 6" wide) to gather as much air as possible and shrink it down (which will in effect compress the air and make it travel faster and be more dense -- ram-air) to the, most likely 3" hose, that fits nicely through the radiator support hole. This should extend as far forward as you can get to the grill. And just like 2Many says, an engine is basically a big air pump - the more you force in, the more you need to get out - through a good quality header.

-

clutch slipping

Ok, so I'll always accept a challenge... :classic: All I could find was this from a Toyota-Chevy V-8 conversion - but it gives a general idea - although the Z's have a much thinner version

-

lights are screwed up!

The extra parts I have are from a 71 also - let me know and good luck

-

lights are screwed up!

Many times you will find that the contacts in the switch are bent, worn or dirty. Remove the switch from the steering shaft and inspect the contacts. The complete assembly can usually be taken apart if needed to clean/straighten out, but be extremely careful as there are small springs and ball bearings in there that are easy to lose and hard to figure out where they came from. I may have a spare set of signal switches/light switch you can have if you can't get yours to work. What year is your car?

-

clutch slipping

The clutch will not work if installed backward. If you lay the clutch plate flat on the ground, the center (metal part) will be raised on one side. The four springs act as dampers to take up some of the shock when the clutch is engaged. This I believe is the rear facing side . In order for the clutch to be aligned correctly, you must use a clutch alignment tool - if you don't you will most likely never get your transmission to line up . The pressure plate springs do get soft over time and may be the cause of the slippage . Whenever you replace the clutch or pressure plate it is always a good idea to replace the throw-out bearing too

-

clutch slipping

Clutch slipping is where the clutch isn't completely sandwiched between the flywheel and pressure plate and it is allowed to slip as the engine rotates. The result is less HP getting transferred to the transmission and a glazed clutch disk and a lot of stink. This is usually caused by weak springs on the pressure plate, a worn clutch disk or improperly adjusted slave cylinder. When this happens you will smell a distinct burning odor (kind of like that of brakes when you forget to take the emergcy brake off any drive for a while). Also, when you rev the engine it will seem like you aren't getting anywhere fast but the engine is revving quite high. Hope that makes sense.

-

How rev-happy are Zs?

One of the weakest parts of the z engine are the valve springs - as they get old, they get soft. This causes valve float at higher rpms and you will notice a bog down when trying to rev. I've had engines that won't rev past 5000 - just felt hollow - because of bad springs - new springs let her go to 6500. Freshening the head with a good quality valve job and new springs will help tremendously.

-

What is a "Spook"

The official material is ABS plastic (Acrylonitrile Butadiene Styrene). It is great because it is innexpensive, lightweight, flexible, easy to work with and solvent weldable. Here's the steps to build an air dam for those who are into the do-it yourself thing... Use corrugated cardboard to make a pattern for the horizontal lip. Lay under the front of the car and hold the cardboard from the bottom against the valance. Using a marker, from above, mark the along the valance on the cardboard. That will give you the arc. Make a 1" line (or wider for that super car look) for the lip. Cut out the pattern and transfer the shape to your ABS (1/8" thick - less than $50 for a 4x8 foot sheet - will make several dams). Next, determine the length and height of the dam and cut that from the ABS. Use a straight edge and a sharp utility knife or tin snips. Place some of the solvent in a separate jar and mix in some shavings of the ABS. This will make a thicker glue - shake it every so often over a couple of days so it melts and mixes well. Use masking tape to tape the dam to the lip (from the bottom) and run a bead of solvent along the seam. Once that cures go back with the thicker glue - make a nice fillet. Also get the back of the seam. Keep things square. Using 1" wide aluminum straps and pop-rivets, mount it to your valance. Last step, drive fast and have fun! I will be building one soon - I'll take some photos of the process and the finished product.

-

Ricez

Might be hard to drive while looking through the MSA sticker on the windshield though :classic:. Does look like a quality job.

-

What is a "Spook"

The little air dam on the blue car would help more for radiator cooling by creating a low pressure area behind the radiator - kind of like a lot of new cars have. Anyway, if you want a less clunky looking air dam but still want the benefits, you can easily build one similar to the blue car's from some polyproplylene plastic sheet. It is inexpensive and it can be glued using special cement similar to PVC pipe glue. As in the comparison picture, extend it down a bit more and make sure to include a 1" wide horizontal lip forward - this is where the glueing comes in. This will force all air that hits the air dam around the sides of the car and not allow it to slip under. Plus the plastic is fairly flexible and won't be so easy to crack.

-

is a ballast resistor needed in a 240 with a 280 electronic ignition

I know with the Crane electronic ignition I put on my 240, they said that if the coil gets really hot within 10 minutes of running, it needs a resistor. I would have to look at the directions again but there were some installations that needed it and some that didn't and some that had it but used a 14 gauge wire jumper. I will look at the sheet again tonight and post some more info if you don't have an answer by then.

-

dammmnn.... check out this Japanese 240Z!!

If you're talking about #17, although it is kind of hard to see at that angle they are most likely Panasport Unltra-Lites. You can get them at quite a few places... - Rallye/Sport - 303-427-0510 - Paul Spruell Racing - www.paulspruell.com - 800-552-2532 - Averill Racing Stuff - http://www.racing-stuff.com/wheels.htm - 248-585-9139 - Motorsport Auto - 800-633-6331 ...and many more... Search for Panasport on google.com

-

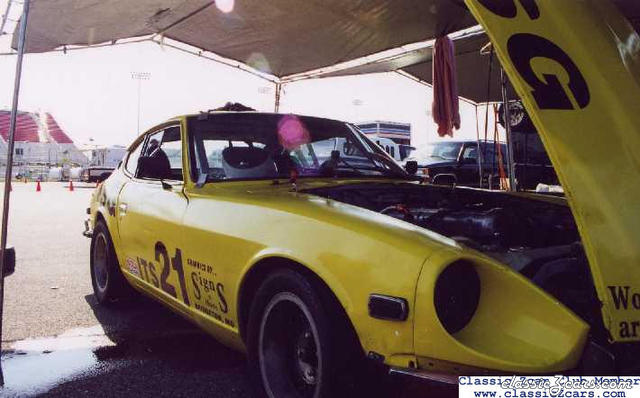

Robello Racing

If you are looking for a really good racing engine or anything in between, also check out Jeff Winter from Rallye/Sport in Colorado. He has been building/racing Datsun 510s and 240s for more than 30 years and builds professional engines. He built Nick Craw's (old SCCA President) unbeatable 240. His prices are very competitive and his products are top notch! His engines give Robello's a run for their money - any will usually come out on top :classic: Jeff Winter rallye/sport 7102 Raleigh St. #3 Westminster, CO 80030 303.427.0510

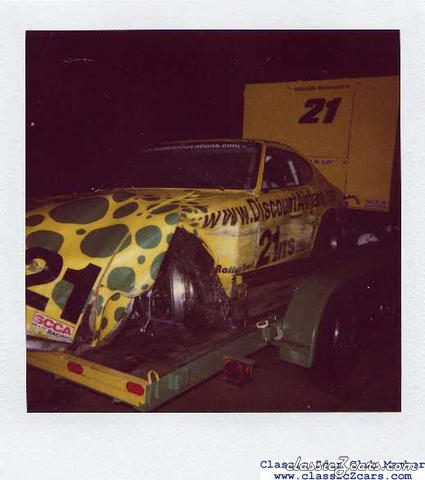

- Ouch

-

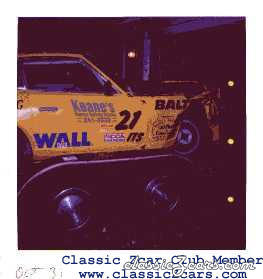

Crusher Bound

- Mushed

- Waiting

-

Swapping engines

-

Needles?

The Grosse Jets won't give you any better performance - maybe just more reliability. I've always had good luck with, and stuck with the stock jets. As far as needles, there are different tapers that you can get. If you are pumping a lot more horse power, you need to feed the engine better. Try contacting Jeff Winter at Rallye/Sport in Colorado. He has modified needles for racing and knows a ton about these motors and carbs. He will be able to give you some great information. Jeff Winter 303-427-0510 (MST) 7102 Raleigh St. #3 Westminster, CO 80030

-

Wont Start.

If you have fuel at the carbs, check to make sure you are getting a spark. Maybe your points have worked loose and won't open. When you pulled the plugs, were they wet with fuel?

-

Airbag?

I used to have an air bag in my old 240.... but then I broke up with her :classic: