Everything posted by aarc240

-

240K GT parts

Kent, Here's one badge that you probably haven't got: http://cgi.ebay.com.au/ws/eBayISAPI.dll?ViewItem&item=230181773892&ssPageName=ADME:B:SS:AU:1123 and I promise I won't go after it if you need it!

-

240K GT parts

Kent, No visible difference between early 240K GL and GT panels. I would think that all Nissan did there was alter the badge to satisfy our rapacious insurance companies.

-

240K GT parts

Lachlan? Which year had this badge? Kent, as Mr Camo has been kind enough to verify, sounds like your panel is most likely usable with new badging.

-

240K GT parts

Kent, You mentioned that the car was complianced 1/73, was it described as a "DATSUN GT COUPE"? If so then we now have five examples of Australian delivered Datsun 240K GT's that have good documentation and provenance traceable to Nissan Australia. At $1500 I would consider that you made a pretty reasonable investment.

-

240K GT parts

Good question. If Nissan have done their usual thing then the panel itself may well have exactly the same holes in it that the original GT one had. If that is the case, just a matter of replacing the badges. If not a little rework with a MIG or TIG welder would be easier and cheaper than sourcing and shipping another!

-

240K GT parts

Lachlan, You're right that some are early vs later cars, just pointing out those that are very specific to the 'earliest' of the earlies. I've inspected a couple of supposed GT's that somehow 'lost' their ADR plates which owners were trying to sell at inflated prices, both were doctored early GL's with no provenance traceable to Nissan. Maybe the 6 digit odometer that I pulled out of a '75 240K is actually a later release OEM replacement part?? Dunno & really don't care! Kent, There is a spare DATSUN badge which could have been any colour (nothing evident now). May have another in white. Like Lachlan, I've seen the black badge but not on a car. I'll get a pic tomorrow of the original on our better car. Rear panel may be a problem, at least in very good or better condition. I have a spare but it's what I would deem restorable.

-

240K GT parts

btw, there's actually a s**t pile more 'little' differences to deal with for a really good restoration! oh, and I forgot about those taillights. They are not original GT parts, they are JDM items. The JDM lights do NOT comply with the Australian ADR's applicable at the time of manufacture and could not be fitted by Nissan.

-

240K GT parts

Kent, there's a lot more different than those few items. Speedo is MPH only, not dual MPH/KPH. Odometer is 5 digit. Oil pressure is imperial. Water temp is imperial. Dash does not have the parking brake and brake system warning lights in the lower right corner. Tacho has the brake system warning light in the lower centre. Air vents are rectangular. Front and rear springs are lower and stiffer. The ADR plate describes the car as a "DATSUN GT COUPE". If you really want to go down the rebuild path, work out your plan and get in touch. I've got a complete (stuffed) 240K GT for spares plus some of the unique parts out of another one. The "DATSUN GT COUPE" ADR plates for those two cars are not for sale.

-

Steering rack upgrades?

A bit hard as I don't know what you have planned! As a simple guide, my tarmac car has 1. longer lower arms for more negative camber and every millimetre of extra track I can get 2. frame rails plate reinforced under the steering box & idler 3. rails also reinforced for stabiliser bar mounts with tube anti-crush and full thru rail bolts 4. custom steering idler with needle roller bearings 5. custom strut brace with tower to firewall braces 6. boxed junction frame rail to firewall (thin sheet steel) 7. every flex bushing is urethane with a grade chosen for each purpose 8. the usual spring, staibiliser and damper changes You are probably going to have to do some development of your own as an RB25DET is sure to require differences. Art

-

Steering rack upgrades?

So non-Oz people understand why the conversion isn't trivial here. All Australian jurisdictions use common base guidelines and one of the major points in altered steering is minmal bump steer. If it hasn't been certified then you don't want to be caught with it on the road or worse still have an accident. It's called 'total liability' for any and all damages and injuries.

-

Steering rack upgrades?

Sorry to say that unless you are prepared to convert everything in the front end to match the 280ZX then it isn't going to work. There is so much difference in the dimensions of tie rods and rack length compared to the equivalent parts on a C110 that bump steer is going to be uncontrollable. Then you put the rest of the cross member assembly in and you need to shift the towers to the same width as a 280ZX. Plus the chassis brackets for the 'rods - tension' need to be moved. All in all, not a trivial exercise. If you are determined to have rack & pinion then you need to start from measurements of a stock C110 sitting on flat ground. 1 Tie rod length (ball joint to ball joint) 2 Rod assy - cross (tie rod inner joint to tie rod inner joint) 3 Height from tie rod inner ball joint to the inner end pivot point of the lower control arm. 4 Travel of a tie rod inner ball joint (either side will do) as the steering is run through it's full range. You don't care about the overall length of the 'rod assy - cross' as it has no influence on the rack requirements. Now you need to find a rack that has total movement at least as great as 4 above and an overall length to the inner ball joints very close to 2 above. A rack that is close and can be modified to suit is the usual answer. Once you have that then you can address the easy part - adapters to convert the tie rod to use Datsun ends and give the same length as 1 above. Last, the new rack has to fitted to the C110 cross member so that the centre line of the rack is in the same relationship to the lower control arms as was recorded from 3 above. Just to complicate the issue, since the C110 has an adjustable height column you will need to fabricate a mount for the bottom of the column to stop that flopping around and then fabricate an acceptable link between that column and the new rack. Do you REALLY want rack & pinion??

-

one shoe was enough

Stainless on carbon steel or on zinc plated steel is just to stop them 'sticking'.

-

one shoe was enough

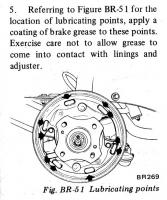

Sorry about delay, been away playing in the dirt. First, the single piston design. If you place a heavy steel band around the brake shoes to simulate the drum and then apply the brakes you will find that the second shoe is applied by reactive force. In other words when the first shoe contacts the 'drum' it will stop moving. The second shoe is then pushed in the opposite direction against the 'drum'. Now ALL the pressure delivered through the single cylinder will be exerted against BOTH sides of the 'drum' by both shoes and the force exerted by each will be half the total. Is it 'strong'? Probably not ideal but the design has been used for a long time by some very respectable manufacturers on some very fast and expensive cars. Twelve grease points per drum setup, see the attached excerpt from the 240K GT export manual. Oh yes, in this version there are only ten grease points!!

-

7/8 or 13/16 cylinder

It all depends on the FRONT brakes you have! If you have the correct brakes for a long wheel base car then the front brake calipers have two pistons (one one either side of the disk) and you would be using the 7/8" cylinders in the back. Tokico was the usual supplier of this combination. On the other hand, if you have the 'ANNETTE' type calipers on the front with a piston on one side only and a sliding frame then you would have 13/16" cylinders in the rear brakes. Nabco appears to have been the usual supplier of this combination. The 'ANNETTE' brakes and 13/16" rear cylinders are supposedly only used on the short wheel base four cylinder cars but I have found them on two 6 cylinder sedans in Australia. Same caution is needed re the manufacturer of the cylinder and the locking plates.

-

one shoe was enough

Single piston design is correct. Watch out for the manufacturer of the cylinder, the locking plates are different for the Tokico and Nabco cylinders. Mix them up and if you do manage to assemble it the brakes definitely will NOT work properly. Also, there are twelve points in each assembly that MUST be greased with a high temperature grease.

-

save them before crushing

That white one on top looks like it has a better spare wheel well than about half of the supposedly good cars I've looked at! For that matter the roof rails are too. "first .... we like to see them ( to look at them ) daily especially before sunsite ( when we drink the coffee and remember the past )" Good on you!! Australians (like our American friends) have generally forgotten the skills and urge to actually rebuild something so unless good easy to fit replacements are available it's off to the scrapheap. And before I get blistered, yes I can and do make my own rust repair panels.

-

Boot (trunk) lid alignment

Thanks for those. I don't have the springs in ours anyway - wouldn't stay open with spoiler on top, safety triangles underneath etc! You're right that torquing the lid at one corner changes the alignment of the other corner but that doesn't affect the mismatched curvature of the right side of the lid when compared to the body line. I'm still not sure but I think I'll just assume it's close and use it for the master.

-

Boot (trunk) lid alignment

On the right side you can see that for about the first third of the lid or so it matches the body shape and then rolls off in a curve that is tighter radius than the body exhibits. The rear trim is noticeably lower than the trim on the body. Compare that to the left side of the lid where it is a close match to the body all the way along the edge of the lid. That mismatch seen in the two images is virtually identical to the mismatch on our GT and there is no evidence on it of any rear damage, inside or out. I have been able to look at a couple more cars around Adelaide plus one I just bought for parts. All three show the same shape in the lid and the same mismatch on the right side so I'm assuming that there was an error in the original pressing of something on the car. Since I didn't think to get an accurate profile of both sides of the boot/trunk opening I'm not entirely sure that it is the lid. Maybe the outer skin of the body shell is actually where the difference is. The lid fits the seal accurately on at least two cars so I'm reluctant to tweak the lid without good reason.

-

Boot (trunk) lid alignment

No one else has a C110 hardtop they can have a look at?? Once the moulds are made then the lightweight panel will match mine, so if it needs fixing speak up now.

-

so i bought another pair of watanabes

Kent, you need to be careful of those rim/tyre size combos. Check it out with an Australian tyre fitting place or talk to your Roads / Transport people. Anything less than 225\50 or 235\60 on a 9" rim and you won't get your car back under the 'hoon' laws.

-

rear disc brake conversion?

Sufficiently different that general principles only apply. Regardless of that, good info and nice work. A bit like the comment earlier in this thread that it isn't possible to weld to the axle housing because it's 'ductile iron'. In reality a 240K has a pressed steel trailing arm that is welded together and there is no good reason why a new caliper bracket cannot be welded to it. Welding isn't "verbotten anyway", it just has to be done by a qualified tradsman (or a better engineer is needed!!).

-

Boot (trunk) lid alignment

Can anyone have a look at the alignment and shape of the boot (trunk) lid on their C110 hardtop please? More eyes that look the better. Have look at the shape of the lid in this http://www.classiczcars.com/forums/attachment.php?attachmentid=18143&d=1178566282 I was about to rework ours on the assumption that it was bent but in fact the right side is virtually identical in shape and fit to the pictiured 2000 GTX-E. The left side fits much more accurately but again is very close to that of http://www.classiczcars.com/forums/attachment.php?attachmentid=18140&d=1178566282 This view shows the 'misfit' on the right side also where the lid obviously curves more than the body and consequently the extreme rear edge of the fender just shows above the lid. Our lid is rusted internally so it will be a 'master' to pull a mould from but I see no point in 'alignment fitting' it if in fact the original fit is generally like that shown. After all, a lid that fits perfectly may well be a lid that does not fit correctly.

-

Unusual Kenmeri QLD

Thanks for that. The car will actually be going to a friends property on which 3 Skyline GTB's live so all usable parts will certainly be saved.

-

Unusual Kenmeri QLD

I could call it 'heart & lung transplant plus a wee bit of cosmetic surgery' but that'd be stretching the truth more than a little. It's really a donor car for things like front uprights, rear axle etc for a 'toy' sitting in the workshop. I'll try to get a pic or two soon of where some of the mechanicals are going. Still 4 cyl powered, just Datsun instead of Prince.

-

Unusual Kenmeri QLD

As part of the suffix T is a floor shift (according to both the export Service Bulletin and Service Manual, I'm still trying to wotk that out in the JDM stuff). Yes, H is actually part of the prefix:eek: I thought it was plain, sorry that wasn't as clear as it may have been! Nothing to do with cars 'seen'. What I was trying to get across: is there any good evidence that all 301 of those first cars were KHGC110's? I don't believe there were sufficient KHGC110's delivered to account for that range and there is a high probability that not all cars in that range had that prefix. Using the number of your car, is there any good evidence that there were 3627 cars all with the prefix KHGC110 delivered throughout the RHD markets between the dates of production (or compliancing) of those two cars? I don't see where that page addresses anything to do with serial number sequences. There still has been no good and valid reason for the claim that each and every prefix has it's own serial number sequence!