Everything posted by aarc240

-

Very Dim Intrument Panel Lights

Tell me about it being the worst colour, could barely see the instruments on a pitch black night with the reostat bypassed and good 5W globes in there. Sure were/are blue. I actually looked at them again a couple of hours ago just to see whether I did keep them. As I said to Kent, if you want them you are welcome to them.

-

Any one fitted Air Con?

As Stephen says, doesn't matter too much. Use the largest condenser you can fit in front of the radiator and leave at least 25mm gap between them. The usual problem with all modified systems I've seen tends to be not enough cooling through the condenser, particularly when switching to later 'green' refrigerants. Funny how some ideas change when The Boss puts her foot down isn't it!

-

OEM size tires on ANY C110 variant anywhere.

Found a little more: 240K GL HGC110 FSM has wheel spec 5.5" J 14, tire 185/70HR14 Still not enough to get away with 255's! Alan, thanks for confirming the body width. I just don't know how much weight that will carry when talking to a bureaucrat.

-

Very Dim Intrument Panel Lights

If you want them, I'm pretty sure I kept a set. My gauges now illuminate orange. edit: just pulled apart a couple of later panels and they are green like yours!

-

240K in middle east

I was under the impression that the '240K GT' badge was unique to the Datsun label. Would not a Nissan 'Skyline 240K GT' be a non-existent car?

-

Very Dim Intrument Panel Lights

I figured the problem was probably 'yellow canaried' (ie defected)! Much the same as 'pink slipped'. Elther way, the oddity of the painted blue domes was something that any owner of an early C110 240k would be interested in.

-

Very Dim Intrument Panel Lights

Razor If you have an early '73 car you may find that it was one of the less smart 'features' from Nissan. On doing a rebuild of the instrument panels from 2 really early cars (both VIN less than 500) I found that the blue plastic dome over the bulbs had been painted on the OUTSIDE. This white paint effectively reduced the light output by about 50%!!!!! Very definitely factory, been done by masking with a slip over mask and spray painted. Also, both instrument panels identical. May be significant that both were imperial (mph) gauge sets. I'd try bypassing the reostat first, then bypass direct from the battery to the gauge side of the reostat. If that doesn't help, pull and clean the bulbs and the multipole connector to the panel. If nothing seems to make any difference, pull the whole instrument set out and dismantle to check those blue bulb covers.

-

KHGC110 240k GT

A better image of the engine bay before I started changing things. Note the Mitsubishi Electric fuel pump on the right hand tower. Physically spot-on alignment to the built in weld nuts in the tower and had Nissan style 6mm bolts securing it. The wiring mated to the 240K harness tidily and even used the oddball 8mm spade on the power wire. Blanking plate on the head, no mechanical pump. Maybe the very first of the 240K's had these parts, later deleted as an unnecessary expense.

-

OEM size tires on ANY C110 variant anywhere.

Have a browse through this: http://www.dotars.gov.au/transport/safety/road/bulletin/vsb_ncop.aspx It should help with understanding what the 'authorities' are now aiming for.

-

rewiring the 240K

Some additional things to make life a bit easier. For mounting 2 or 3 relays in some spot, get the mount plates, screws, relay bases and a chunk of harness from a junked 1985 onwards Ford Fairlane. For relays in those, collect some from VL and later Commodores. The ones you want have the 'internals' diag molded into the side and on that diag you can see a small rectangular block in parallel to the coil. It's a 'snubber' resistor which suppresses the back EMF pulse which normally occurs when a relay switches off. Very good when ECU's get into the car! Watch the terminal configuration - there are a few variants in those supposedly standard relays! It's a good idea to source the relays from one make & model but not always feasible. If any differences are necessary, document it in your own wiring manual for future reference. If you solder any terminals, use heatshrink tubing for strain relief to at least 15mm down the wire. Otherwise you WILL get vibration breakage where the solder ends and plain copper strands start. Make sure you source from the battery as direct as reasonably possible for electronics. Use a common earth ('chassis') point for everything you can. Obviously front and rear lights etc don't have this but at each end of the car make a good solid connection to chassis and use it. Scraping a circular patch to bare metal and then 'tinning' that gives a good long term solution, but a clean bright patch of metal with a thin smear of grease is nearly as good. Any terminals bolted to either of those will make good connection.

-

rewiring the 240K

OK, you have what you need in the R33 engine diag, the RB25DET (source car) engine diag and the C110 diag. First off, in the body you only need to replicate the C110 plus any desired extras and with addition of any RB25DET related wiring you wish to make integral to the finished harness. I wouldn't be inclined to do that myself, preferring to keep the engine to ECU harness with all sensor wiring etc as a completely seperate unit with ONLY the essential interconnections for 'ignition on' signal etc. Have a browse on http://www.msefi.com/ forums for ideas on creating a good engine harness. On the body side of things, make out a list of the 'extras' you want like driving lights, electric fuel pumps etc. Work out how you need these to operate and where any interconnections need to be (electrically). If you have a decent size shed floor to work on it will be easier to draw out the C110 profile full size. Mark in the postions of components (fuse box, lights, pumps etc etc). At each position add info for distance above car floor. Start laying out your colour coded wires on that 'plan' and you will be surprised how quickly you will see what is needed. Remember to allow for the height above your car floor reference plane - it's a three dimensional thing. It's a good idea to leave extra wire at each termination point, that way you can tape the harness together at say 300mm intervals (and every branch point) and trial fit it in the car to determine just where you want to cut the wires. While laying out the wires, use a photocopy of the source diagrams (enlarged if need be) and mark off each wire with a pencil as you do it. With a first time harness, just break the job down into smaller chunks. Say the front light wiring as one task, the rear body wiring as another, etc. When it all seems too hard, remember that people wire things like Space Shuttles successfully. And do ask for help.

-

OEM size tires on ANY C110 variant anywhere.

Thank you Alan and Kent. I will use the 280ZX argument then. Kent, I sure hope the engineered approach works for you but it might be doubtful. The 1.3 x (widest optional fitting for that model) rule is part of the 'National Code of Practice for Light Vehicle Construction and Modification (NCOP)' and since each State and Territory is a signatory to that Code there could be some serious resistance to going outside the Code. By 'modifying' the suspension with 280ZX parts and going with an approval for that I have a new track and wheel spec based on the 'uprated' components!

-

OEM size tires on ANY C110 variant anywhere.

Who has data on tire width fitted to any and all C110 cars, regardless of variant or market? Related would be track of vehicle. We know about the 1.3 rule but .... I have 245/45ZR16 on front and 255/45ZR16 on rear, neither of which comply with the 1.3 rule. However because I have used 280zx front hubs (they are almost identical to C110) and 280zx rear stub axles (not quite a bolt in but not hard) it appears that I may get away with using the widest tire from the 280ZX as the base size. Naturally DOT would prefer to have C110 specs as the base so that a precedent isn't set. So, the ideal is to be able to show that a C110 SOMEWHERE had an optional tyre size at least 195. Can anyone help?

-

KHGC110 240k GT

My German is very rusty so it will take some time to translate. One thing I did notice on first scan through is that the hardtop is specified at 1240kg. That's a LOT heavier than the 1973 240K GT hardtop which was specified at 1130kg. That would indicate there were some pretty significant changes!

-

KHGC110 240k GT

Must get myself a C110 Skyline Factory Service Manual. Then learn Japanese so I can read the dang thing. It would be VERY interesting to thoroughly compare the specifications of the C110 Datsun 240K and the C110 Nissan Skyline.

-

KHGC110 240k GT

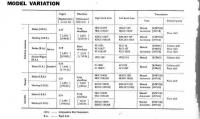

The upload does some strange things ! The attached images should be better. Nothing in the FSM in the way of part no's but you should have that from the parts book. Interesting to note that Nissan used 'P' to specify the G18 engine in the 240K when they apparently stayed consistent in using 'P' to specify the S20 engine in the Skyline. Just those two pages alone are a pretty clear indication that as far as Nissan was concerned the 240K may have shared the same basic body with the Skyline but that was all. Codes are not even remotely related. The G16 and G18 engines shown are unmistakably the old Prince four cylinder units! Did the Skyline use those or L4 engines? I have no idea whether the Skyline even had 4 cylinders available. An observation from a former Datsun dealer was that the second manifold could well be from the L20(a) Laurel engine. Apparently that used a different manifold again, possibly somewhere in between in configuration.

-

KHGC110 240k GT

Just an idle thought... In other markets such as Europe and Britain, Nissan wouldn't have fitted one manifold to the hardtop and a different one to the sedan, would they? Or maybe associated with a different transmission option? Are there any British or European members out there who can post some photos of their engine together with some documentation like model code and build date?

-

KHGC110 240k GT

Aus FSM won't help much as it refers ONLY to the '240K GL' and shows the basic manifold. I would be very interested to get some scans of documentation that actually shows that the manifold was discontinued in 3/1973. Have a look at your first link posted above - it appears that we have a German market publication from 1974 that refutes that!

-

KHGC110 240k GT

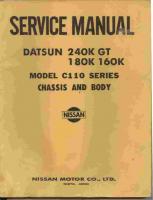

I was already aware of that thread and can only say that all it adds is more supposition without facts to back up the assumptions. Seems like your interpretation of the factory codes and Nissan's are rather seperated. See the attached images scanned from the Factory Service Manual for the Datsun Model C110 Maybe Nissan wasn't reading from the same script 'cause they think that G stands for long wheelbase and H stands for L24! As a matter of interest the FSM for the Datsun HGC110 series titled "Datsun 240K GL" defines exactly the same codes. I thoroughly agree. Homework isn't a problem. You see, I was actually around at the time, already a young adult, a qualified tradesman and deeply involved in motorsport. Morris would have been nothing more than another windbag in Parliament had it not been for Green who had ALREADY been creating trouble with his stirring. I already have copies of those mags (in fact my copies of Wheels March 1973 and Sports Car World April 1973 are the originals I bought new from the local newsagent). Lots of confusion, plenty of windy wordage in the articles and really skimpy on facts.

-

KHGC110 240k GT

Ridicule? Sorry if that's what you assume is the case when I pointed out that Nissan made the manifolds and still does. Um, recall and rebadge? Not likely unless they wanted to get into all sorts of fun with law suits. I doubt there are too many mugs out there who would happily accept ANY manufacturer telling them "so sorry old boy, we really didn't sell you an XYZ Super Wazoo for lots of money, we really sold you an XYZ Wazoo that isn't kitted out as well and we are going to take the Super off it whether you agree, like it, or anything else" The software industry might get away with that sort of garbage but try it an a man's car and see what happens. He OWNS that thing and by golly, it better be exactly what he thought he was getting or someones gonna lose his cojones real quick. I agree that in JDM and other markets where the 240K was sold the 6 cylinder is a GT. There is even that distinction clearly made on the front cover of the Factory Service Manual (quote "Datsun 240K GT 180K 160K") In the Australian market the majority of these cars were 6 cylinder GL and it was Nissan's choice to do so. Again that is clearly stated on the front of the FSM "Datsun 240K GL" Interesting the statement that the 4 cylinder was a GL in other markets. The factory manual doesn't mention it. In fact according to the FSM 'Model Variation' table there isn't any such thing as a 4 cylinder hardtop either. As that FSM was published in June 1974 there may well have been changes after that (and AFTER Nissan started badging sixes as GL's in Australia) I would be interested to see proof of '240K GL' badges from any source that refutes the information shown in the parts list at Section 353-1 and 353-2 where NISSAN states "FOR AUSTRALIA" over each image of a 240K GL badge and alongside the listing for each of those badges. Like it or not, there ARE differences in the GL and GT variants. We own one of each in hardtop and a GL 4dr. The GL hardtop doesn't perform as well as the GT hardtop but that can be mostly attributed to the diff ratio. For some reason known only to Nissan the GT got a 3.9 ratio where the GL has the 3.545 which the FSM's say BOTH sholud have had. Is the GT better than the GL? No, they are just different.

-

Interior Photos

Bugga! I only have a somewhat dirty light grey one from a 4dr but the spacing of the supports look pretty much the same. If you get stuck you are welcome to that for a pattern and I can always measure the 2dr one to make sure.

-

Interior Photos

If you need closer images, give a location reference based on one of those images eg upper left quarter of pic ......

-

Interior Photos

-

KHGC110 240k GT

Right on the first one, you can see the swept curve in the front runners and the angle of geparture of those from the central chamber. Wrong on the second pic, it's also a GT manifold. Have a look at an L24 basic manifold and you will see that the front runners depart the central chamber directly forward parallel to the head. Have a closer look at the pic and it is obvious that the front runner departs at an angle pointing towards the front centreline of the engine. Compare it to the first and you can see that the angle is pretty much identical, allowing for different camera perspective. Also the centre runners ARE longer than the basic L24 manifold in the pic. Print it then accurately measure both the diameter of the radiator hose and the length of the centre runner. Measure a real hose. Divide the measured runner length by the measured (pic) hose diameter and multiply by the real hose diameter to get a very close approximation of the real runner length (this is a standard basic engineering technique called 'scaling'). The result is a figure some 15mm LONGER than the centre runner length of a basic L24 manifold as fitted to a GL. Given the two clues above it's pretty safe to conclude that the second pic is also of a 'GT' manifold. Why would Nissan drop the GT manifold here? I would think the amount of resistance to the idea that a GL is not a GT would wise people up. If you had a GT in England and saw advertising from Oz for a GL you would quite reasonably assume it was a down spec car. If you then discovered it had exactly the same fit-out including performance parts then you would be pissed off (and rightly so). I wouldn't fret over it though, after all who else in the world has a 6 cylinder 240K GL? Ours is a common ol' GT as marketed in several countries.

-

KHGC110 240k GT

Maybe it wasn't too clear.. the ONLY L series engines I have ever seen that manifold on or have ever seen documented as having that manifold were the L24's fitted in the 240K GT as delivered in Australia in early 1973. The Skyline FSM shows different manifolds ranging from the basic L24 unit through twin side draft Hitachi but not that particular one we saw here. The 240K GL FSM shows the basic L24 manifold only. I too would love to get feedback from Europe, Britain and NZ.