-

Installing a air/fuel ratio monitor

I'm with BOOSTEDZ..... The one you speak of is only a narrow band sensor and should NEVER be relied on to be accurate. Slightly better is a Bosch LSM-11 but the best ones out there are the NTK or Bosch UEGO sensor. I have a motec PLM which uses either sensor and cost about A$2500. Remember, you are not going to get a lab spec unit for a couple of hundred dollars. Some high output engines can be quite sensitive to small changes in fuel delivery. I recently did some testing of another bosch UEGO sensor Vs the PLM and the results were quite interesting. At light load the 'cheapie' (A$500) was bouncing all over the place but the PLM remained steady. At Medium load I observed AFR's to around +/- 0.4AFR (almost always to the richer side too) but at WOT they were within 0.2AFR. This means that getting full throttle mixtures should be OK but part throttle/transition may be difficult. Both units were tested with the brand new sensors/pickup points swapped and the units recalibrated for each sensor. At least the results were repeatable. But remember, be sure you know what you are doing if your going to play with fuel curves. ALWAYS start out rich and lean it out, not the other way. Ignition timing will also have an effect on your mixtures and EGT's.

-

O5L Head

I have one here. It's off a L20ET. Yes, the ports are tiny, but the walls are quite thick. You can port them out and make 350rwhp, but stock rod failure is immenent. They have hardened seats as they are an unleaded motor. It was never fitted to Aust skylines, only 2nd hand motors or in low production imports

-

Which head is best..

This head is off a L20ET (2l, 6cyl turbo efi) motor. Runs 7.8:1 comp. can make 350RWHP, but the stock rods are prone to snapping. Don't worry about the numbers, they were an experiment.

-

Which head is best..

For a turbo an N42 will work with the correct piston, but a ported P90 manual lash head is the go. I've made 465rwhp (atleast 550hp at flywheel) on a ported N42, but i'm currently welding up a P90 to improve flow. On the same note i ran a N42 with about 10.5:1 compression with a low boost turbo (12psi) and that was a great package too. Made about 280rwhp. Stu:

-

This some kind of backyard head improvement?

Yeah, i understand that may have been the way for an emergency or low buck fix, but long term durability ???????? I'd be more concerned about the sharp edges causing detonation. take a quick look at the photo. see how much carbon is in the chamber. those hot spots around the punch marks will ENHANCE the chances of detonation, so that's 2 good reasons not to do it. remember, we often run our motors hard and a dropped valve is going to ruin anyones day. I've seen people centre punch tailshaft yokes to do the same. More often than not it ends up in a big mess. think, grenade with pulled pin.

-

This some kind of backyard head improvement?

I can't believe some people repair heads like this. el cheapo & bodgy come to mind.They had loose valve seats and did that to try and tighen it up. don't even think of trying to expect any sort of safety with this setup. get it fixed before you drop a valve and get the detonation accelerators(punch marks) welded up whilst rewelding the seat area. better than new when done properly.

-

another 'whats my problem' question...

Sorry about the crappy drawing. no it won't as your presurising the cylinder side. I've also had experiences with valve stem seals coming off if you have worn guides. checking for these, look closely through the valve spring and see if they are dislodged. But the only surefire way is to remove the valve springs and check clearances with precision tooling. but you have to remove the head again..... :-( But comp so low....... I suspect bottom end. I made a tool to remove springs on the car without removing the head. but this won't truly establish valve guide wear. If it were me, I'd pull the head, strip down and check. Have it pressure tested whilst off. if it checks out ok look for bottom end problems. There could be so many factors creating this situation your experiencing. pressure adaptor.bmp

-

another 'whats my problem' question...

Geez, you'd want to have bad guides for such low compression. It's a rather large leakage path by the sounds of it. May I suggest you try a leakage test. this will pin point the leak nice and fast. easy to do.. you'll need a few things though. 1. an old spark plug 2. a section of 10mm or 3/8 tube about 15cm long (6") 3. a fitting to suit your air compressor line. 4. Silver solder AND brazing rod. flux for both too 5. Access to an oxy torch 6. An air compressor 7. a 2 foot length of 1/2" hose. get an old spark plug and break out all the ceramic. don't damage the threads or gasket on the end though. Find someone with an oxy torch. have them braze in the tube into the threaded spark plus remains. grind off the ground electrode. silver braze in the air line fitting onto the top of the tube. silver solder stops brass fittings from melting when joining. if it's steel, use brazing rod. will look like this when done _________________________:---:______ ==== / ///////] ==== \ _________________________ _//////_] <- Old s/plug :---: /\ Air line fitting sorry about rough drawing. Procedure :- remove all spark plugs to make engine easy to turn over. remove tappet cover and turn your motor over until both cam lobes on cyl 1 point UP. put your handbrake on and chock the wheels. put the car into 4th or 5th gear and release the clutch.(an auto would need the inspection cover off and a screwdriver to lock the motor. This will stop the motor turning over. fit your air delivery adaptor into plug #1. apply 30psi pressure. Use the 1/2" hose like a stethescope and listen to 1. Exhaust pipe 2. Open the throttle and listen down the carby or throttle butterfly 3. Poke the hose down the front timing cover. If you hear air rushing air @1 - burnt/damaged/incorrect valve clearance on EXHAUST @2 - as above, but INTAKE valve @3 - leakage past piston/rings This is a hard and fast method. If you don't have an air compressor, you can use a tyre as a storage vessel and fill it up at the local servo. adapt the hose as necessary.. Hope this helps Stu

-

throttle body question

Putting on a larger throttle body would only develop MORE power if your current t/body is proving a restriction. I suggest you perform a little bit of testing. So I suggest that you go back to the dyno and have them put their vacuum/pressure sensor onto your intake. (You can tap into the fuel pressure regulator hose with a tee). Run it from 1500rpm to whatever your maximum rpm is. WATCH the guage and see if it start to show vacuum at higher RPM. The other way is to get a vacuum gauge and go for a fang up the road. (The bigger gauge the better - more senstive) Have a friend watch the guage, or (as I do with AFR's), use my mobile's vid recorder. Have them watch the guage and call out, 2000, 3000,4000 etc. You'll have video AND audio to watch later. If the tb's too small, vacuum will INCREASE the more you rev it. But be warned, a non liquid damped guage will vibrate rapidly and be hard to read. Anything more that about 1-1.5" vacuum and your tb's or intake plenum is too small. Plenum volume has an effect on relative airflow through the throttle. Bigger plenums act like a buffer zone reducing pulsations(in conjunction with a BIG cam), which can increase effective t/b flow. Remember also that a larger t/b makes your car feel faster due to the fact that at say 50% open you may be getting 75% of the smaller t/b's airflow. I use a Ford 65mm on my L28 turbo. This runs a fabricated manifold though and makes a minimum of 550hp@motor (465rwhp/347rwkw).

-

L24 L26 L28 Dyno results

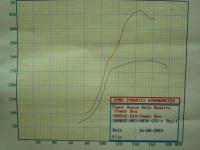

Yeah, i'm in Queensland. No, I hadn't offered it for sale before. I've slowly developed it over about 8 or 9 years. had a lot of crankshaft failures early on with the LD28 crank. used to spit out the keyways and chuck a balancer. been using a modified l28 crank with ok results. the power is fairly brutal. makes boost at about 2500rpm, but it's not usable. wastegate starts to control boost at around 3500rpm. from 4000 to 7200 hang on. The blue line was what I ran at the townsville auto show in 2002. but i've done a lot since then.

-

L24 L26 L28 Dyno results

Been building the ultimate L series for a few years now. Here's the last 2 combo's. I did the lot, except for some precision machining. First one (blue line) was a high compression low boost effort with a different gearbox. made about 280hp. The monster red line was my last combo. Went 465hp @ tyres, which is atleast 550hp at the motor. 4 people in the boot couldn't stop it wheelspining either. Consists of F54 Block + 1.5mm o/s pistons Forged pistons/total seal rings billet rods modified l28 crank welded up and reshaped chambers/ports N42 head custom exhaust, intake and intercooler MoTeC M48PRO ecu + suitable fuel system New one being built now.I want 700hp or more at motor this time round. Stu.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.