Search the Community

Showing results for 'headliner'.

Found 793 results

-

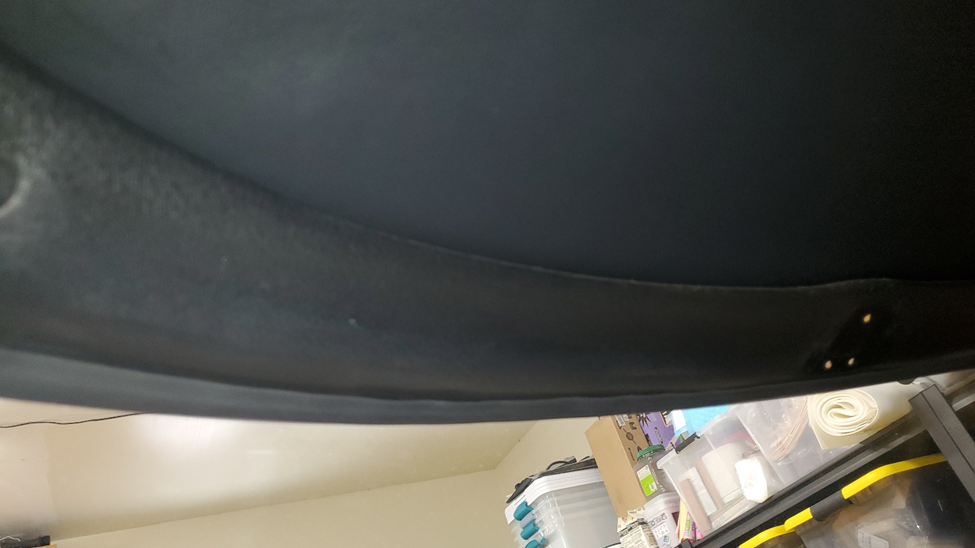

SN 00042 Restoration; The Older Twin

The body is just about ready to send to the body shop. I removed the glass, all items on the underside, and all of the body panels. I scraped off the old weather stripping and am now just doing final cleanup. I still need to drill and tap a few of the rusted out bolts as well. I will make an assessment of which patch panels we will need so shop can weld those in. The nice surprise on the car was the good condition of some of the interior parts. The headliner and A pillar vinyl is perfect as were all of the rear plastic panels, except for the rear panel which a PO had modified for speakers. Also, the doorsill plastic was in good shape and just needs to be cleaned. This will make the interior much easier to restore as some of the aftermarket items for these items are not the best. Often, aftermarket panel holes don't align and I have had headliners where the manufacturer's glue is poor with the vinyl detaching from the foam in hot weather. So, having these items in good condition will be a nice help. Latest photos are below.

-

New to me, 280Z...

Back from my trip to India and got around to working on the car. Got all the fluids bled and topped off so I think it's ready for a rip... after that it's lining up all the panels, buffing, and doing some detail work like headliner, interior, hooking up lights, etc. Thanks for all of your help to get me this far!

-

Transmission Tunnel Heat Pad Insulation - Alternate Template Approach

Update. I've started dry fitting the vinyl and noticed that the traditional cutouts for the seat rails and the typical pattern of slices near the firewall as it curves would expose some of the padding I just laid down. Didn't like that so took some of the old headliner I just replaced (so glad I kept the skin) and placed pieces to hide the grey padding once the vinyl is done. i used the same scotch tape from the headliner experiment and it works great. I'm using these pieces as a test run to see if this tape can be used for the actual vinyl itself rather than messy glue (just like i did the headliner). Here I did the entire under heater core box, looks great and the rails

-

Headliner Install - Alternate Approach

Things are coming together quicker than expected and I got to the headliner today. I had purchased one from the z store almost two years ago but was severely delayed with the project. It came with the typical spray on glue but before IO went to tackle this i had a moment of hesitation. I still have the dash in the car and the thought of over spray and drippings of that glue (its 104 today in Roseville) really had me pause. I was thinking about the recent dynaliner experience with the peel off backing and thought why not do the same for the headliner. So I went to the home depot near me and after looking around decided on this since it was the stickiest, had a high temp resistance, and was relatively thin compared to others of the same strength a single roll ended up covering the entire liner in strips from front to back about 3 in apart. I made sure not to get too close to the ends on all 4 sides since I knew I had to tuck under the edges. TIP - Make sure to draw center lines in both directions and place some painters tape on the vinyl side to match so you can see the tape when attempting to stick to the ceiling. This allows for easy orientation with the center of the mirror mount and the lamp light cutout. I started with by doing the soundproof (highly recommend, the roof now is like a modern car After laying out the tape on the back of the pad I used the same 1 inch roller that I pressed down the soundproof to really press down the tape onto the back of the liner. I made sure it wouldn’t peel up without some real tugging. Once I was happy I pulled the red backing from the center line only and attached it to the roof right down the center line using the painters tape as guides I then worked on the passenger side first removing all red backing and carefully working from center towards door fram pressing the liner up onto the ceiling. Was very happy with how smooth and easy it was and did the driver to match. When I was done I had about 2 inch of material exposed on the doors frames and an inch or so on front and back. TIP – DO NOT BE TEMPTED TO TRIM, it will all fit with gentle tucking The front is the most visible so I decided to start dead center with a tool for scraping glue from windows I was surprised how easily it tucked under the front and went from center to edge in both directions in maybe 45 secs I then went down each side to the turn at the back and finally across the back. Finished product looks factory new! Time will tell if I took an easy way out and this droops from heat or deterioration of the pad but I feel it was the right thing to do considering my circumstances and doing the least amount of harm to the dash 😊 Total install was less than 20 mins, way faster and less messy than spray or roll on adhesive in my opinion.

-

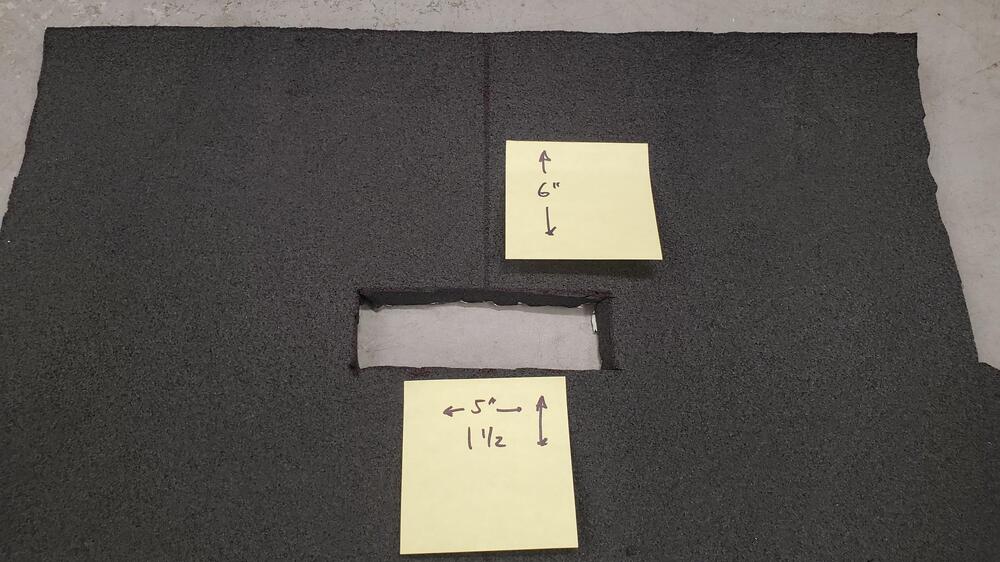

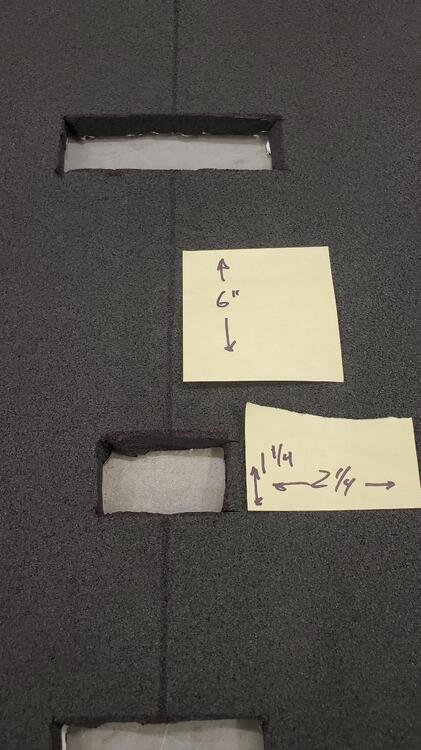

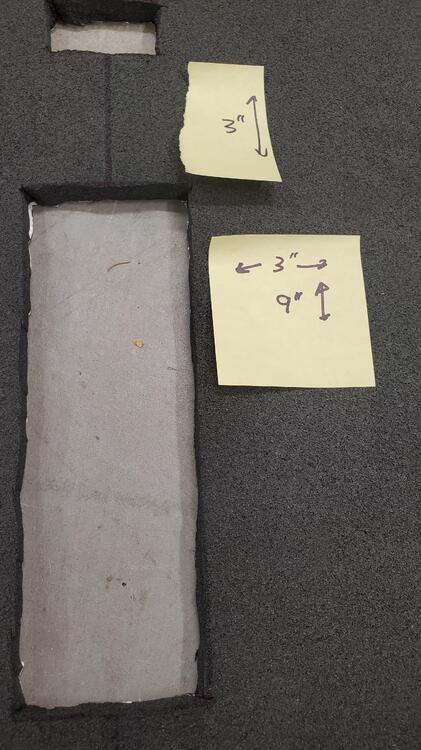

Transmission Tunnel Heat Pad Insulation - Alternate Template Approach

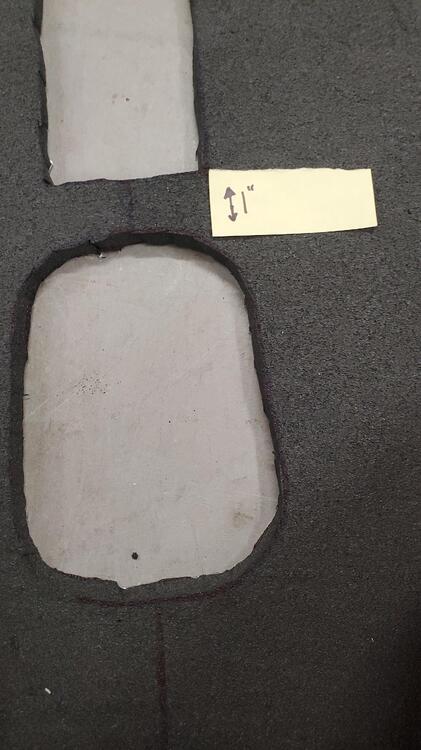

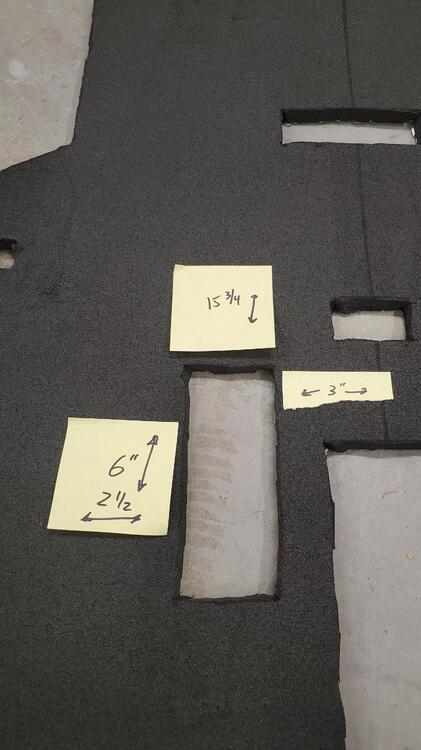

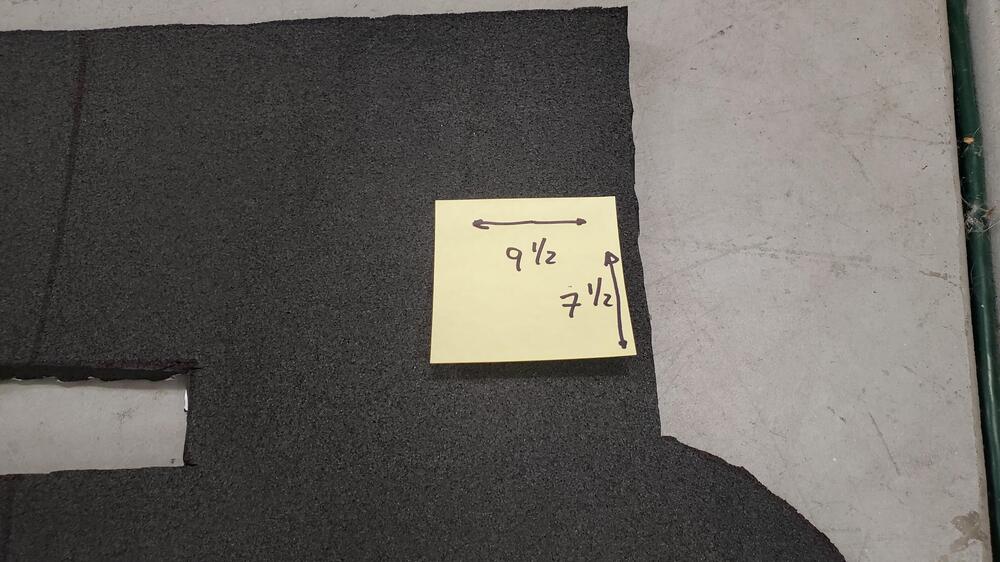

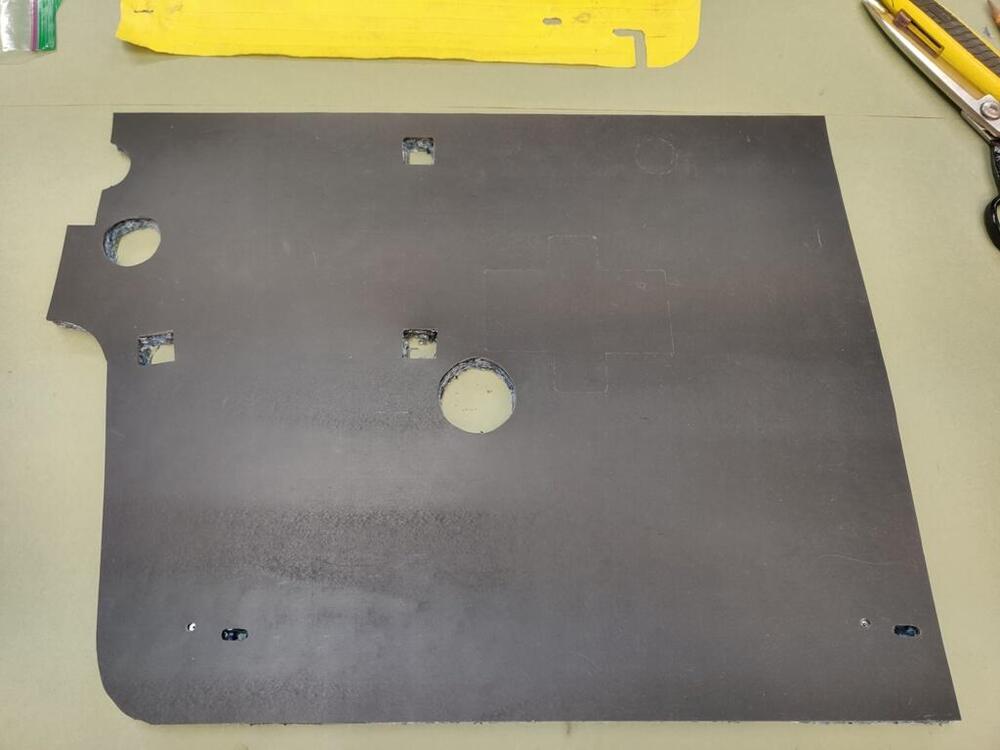

I'm at that point that i needed to put back the insulation after restoring floorboards and sound deadening. I had done my research on here and found excellent material with large printer format templates for the cutouts but I didn't have a printer to do it on. So I did it the old fashioned way with cutout by cutout tailor like approach. i made measurements along the way if its helpful for anyone without the ability to use autocad or a large printer. I decided to start with the dynaliner material i had seen on here a few years ago when I was ripping the old matted disgusting wool pad out. This stuff seemed easy with stick on backing and a great smooth surface for the eventual spray on headliner cement for the vinyl . Here it is if anyone hasn't seen it on amazon https://www.amazon.com/Dynamat-11103-Dynaliner-Self-Adhesive-Deadener/dp/B001JT5NIU/ref=asc_df_B001JT5NIU?tag=bingshoppinga-20&linkCode=df0&hvadid=79989522876749&hvnetw=o&hvqmt=e&hvbmt=be&hvdev=c&hvlocint=&hvlocphy=&hvtargid=pla-4583589102084678&psc=1 If you layout the piece you get its pretty close to the exact full length of the tunnel from firewall to rear tunnel at the hatch. (I have an early 71 btw, maybe a slightly different length for the series 1?). Now I do have to admit, this probably would have been easier if i took the dash out, but i decided to do it in a few smaller sections instead to avoid that. My first step was to do a full single piece from the hatch to the dash mounts on the tunnel. Like many others, i started with a center line to help orient things. My measurements ended up being 42 1/2 " from those mounts to the hatch so I cut that first section out of the full piece leaving the full width. Here's the final with cutouts and I'll get to the dimensions of each in a minute Oh and I see you get some bonus toes thrown in for good measure! I then laid the piece out with the center line down the tunnel and made my first cut for the console mounts by measuring from the back of the piece forward. it was 6 in exactly and the rectangle was 5x1.5 then to the other mount measured from the first cut to the next, again exactly 6" and 2.25/1.25 then to the choke location, same method from previous cut to new cut 3" and 3x9 the last easy center line cut was only an 1" and I used the inner shift boot as a template next cutout for the brake was a little different since it was off center. i took measurements from the rear as 15.75 and from centerline as 3" making a rectangular cut 6x2.5 that was all the difficult ones and the pad fit near perfectly which had me very pleased. What i did next was to start by measuring the back section of the tunnel which was the shortest and easiest to cut, again measuring from rear and centerline to the "curve" where the tuinnel meets the raised floor behind the seats. IMPORTANT TRICK, use painters tapoe when measuring curved surfaces then just layout the tape on the pad and slice. My measurements were 9.5 from center and 7.5 from rear to the point where the floor starts to curve. the other side was symmetrical so i did the same all that was left were seat rails, again measuring everything from the rear and center line on the pad rear rail was 11.5 from rear and 10.5 from center with a narrow .5 slit front rail again from rear of mat was 25 from rear and 9.5 from center with again .5" slit but in the shape of an L (sorry no pic) Again both sides symmetrical so did the same on the other side last step was to place it on the tunnel and then just follow the contour of the floor to trim as needed and to trim around the fuse and lighter mounts. IMPORTANT TIP Make sure to fit not once but twice everything dry wiothout removing the backing until you have it just right Once this piece is in you'll have the hang of this and all the tough parts are done, the rest is to use the scraps to fill in the easy parts under the dash. most of these are square and you can use the painter tap trick to get exact lengths. make sure to leave enough overlay at the bottom and just trim to what you need. Some shots of final product ready for vinyl I'll probably have to trim around the fuse box and lighter mounts, maybe even under the radio before i put it all back but i wanted to cover everything i could and work backwards as needed rather than try to add little pieces after those instalations. Not concourse, not perfect, nothing magical but hopefully helpful for someone. BTW, the single piece of dynaliner may run you a little short, I think i may have used some scraps from a previous piece i had for something else. I cant tell since all the scraps ended up in one pile where they were coming from but its real darn close if you are economical with your cuts.

-

Dave W 1971/240Z rebuild

Sorry man, I'm sure you can understand that I've been a little distracted! I got the muffler on the car last Friday, and spent a couple more hours driving around on the way home. For the benefit of everyone else, there were a few outstanding items when I picked the car up (none of them were Chris's problems - they were almost all parts that I hadn't ordered or that we were waiting for). The missing muffler was the most notable item, so it was good to get that completed. I had to remove all the spacers from under the driver's seat. That tells you how much the original seat cushions had collapsed, because I never had any trouble fitting in the car back in the day. Even with all the spacers removed I'm brushing against the headliner with the seat back and reclined. The rear sway bar links that I'd ordered months ago were the wrong ones, so the sway bar was in place, but not connected to the suspension, which was the suspected cause of a clunk happening when hitting bumps. I got the correct links (unfortunately I mistakenly ordered only one first and had to order a second) and installed the second one this morning. Unfortunately, the clunk is still happening, and I'm starting to think it might be coming from inside the passenger door. The other suspect is the gland nut on the passenger side strut. I might not have tightened it down properly when I re-assembled them a couple of years ago. The tach isn't working consistently, so I need to order and install a TechMatch device to sort it out (I believe it's the TachMatch TM-03 I-Drive that I need? Current-driven tach?). I'm not confident that my ear is good enough to recognize redline, so I probably haven't gone past 5000 RPM yet. The engine sounds and feels absolutely great up there, though, so I'm looking forward to really trying it out. The throttle's a little sticky, which made driving without a muffler quite interesting. It's either getting better or I'm getting used to it. The linkage all looks fine and all the pivot points are properly lubricated, so I'm going to keep driving to see what happens. The gas gauge isn't working, which is mysterious, because Chris and I both had the sending unit working properly, and I think I tested it once when connected to the gauge in the dash. It's probably something simple, but I haven't got to that yet. Mostly I've been driving the car, which has been fantastic! It's starting to come back to me. As I mentioned somewhere a while back, the engine somehow feels much larger than it really is when you first start driving it. That long hood has something to do with it. The car's already starting to feel smaller and more nimble to me after only a few hours of driving. I'll keep driving and knocking these items off, and I'll keep this thread updated!

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Early hand throttle cable attachment under cowl spot weld pulled out. Drivers floor has a couple of rust areas, under seat as well…… more inspection needed from underneath to determine if new floors, or replacement of rotten areas. Firewall looks perfect Neat inscription/stamp “Speedo change” over passenger visor area on edge of headliner and proof that headliner had been dyed to black…. Originally a green/ tan car

-

New to me, 280Z...

I went with everyone's recommendation and had the glass installed with the original rubber seals. I'm just going to leave the chrome inserts out. If any needs them, reach out. I know I have the entire rear glass section and a bunch of random corner pieces. Other than that, interior is basically done with the exception of a one or two trim pieces and the headliner. Next things to tackle is the motor refresh....

-

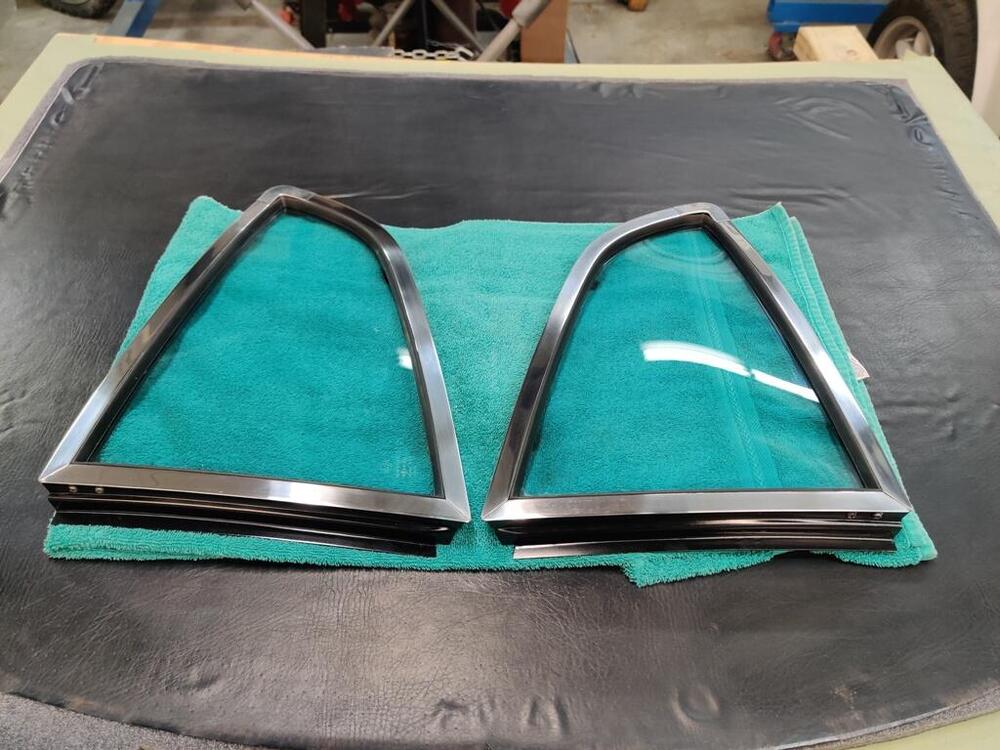

Restoration of BringaTrailer 240z - HLS30-35883

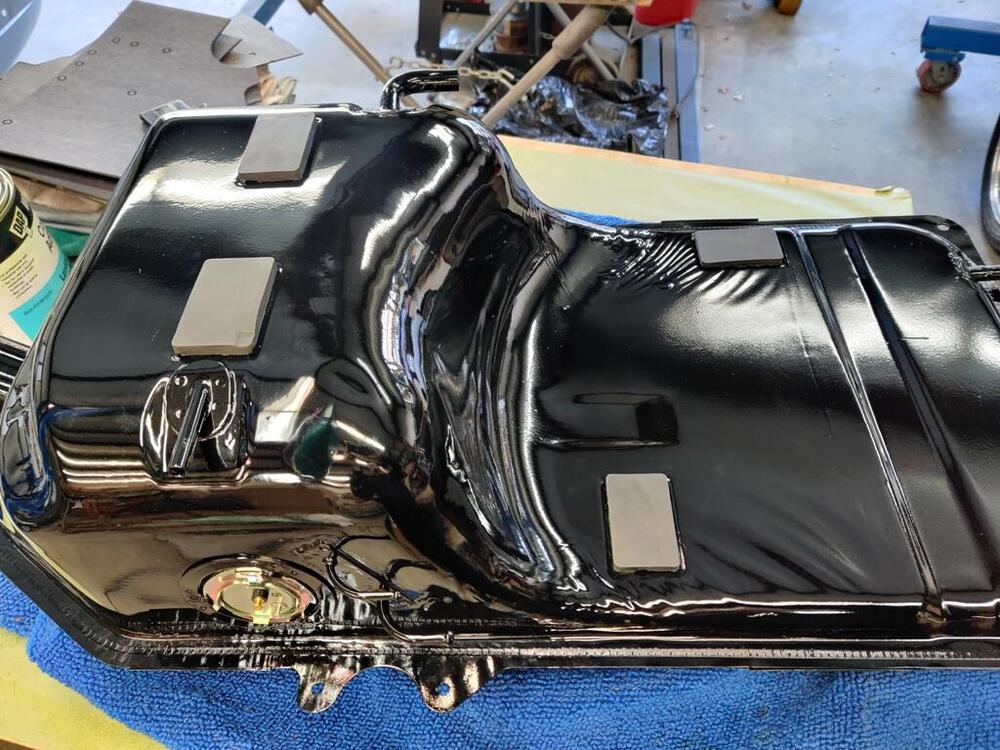

Yesterday, I completed the very difficult task of installing the vinyl A-pillar/side trims. I took my time. I found it helpful to examine the old ones very carefully while trying to get the new ones installed properly. I discovered that the quarter windows have to be out to install these properly. So, I had to take those back out temporarily. Like many things, it is a whole lot easier when you have done one. The second one was much easier and took much less time to install. The only part that didn't turn out perfect is where the side welting butts up against the header. I left a bit more vinyl material there than I should have. If I could do them again, I could get them perfect. But, it isn't worth spending all the time and effort to rip out these, cut new ones and do another install. I found the clips to be more useful with these because I wanted the vinyl to stick to the inside of the weld flange too. It sticks perfectly to the outside of the weld flange without the assistance of the clips. But on the inside, the vinyl is at an angle pulling away from the flange. The clips help it seat there. I had today off from work, so in addition to the usual weekend hours, I was able to spend another 6.5 hours on the car. 🙂 The rear hatch glass has been sitting in a corner waiting... for the scratch remover kit I ordered to show up, and for me to devote time to removing the scratches. The kit has arrived: I found out about it on Youtube. I was intrigued when I saw a video that showed removal of a deep scratch. I had used Eastwood's kit, and found that it was barely adequate to remove some light wiper marks from my BWM M3 windshield. That is not a fault of the product, but I did not realize until I saw this video that there was a product that could remove deep scratches. But, I did not choose to work on that today. Like the rear hatch glass, I cleaned my windshield and installed the NOS rubber weather strip on it. I bought the windshield a few years ago when I was finding it hard to source a windshield without the blue "stripe" of tint across the top. It was made in China, but appears to be a decent quality one. I am going to wait for a warm day and put the windshield out in the sun. I want the weather strip to heat up and relax in the sun before I attempt the install. I will do the same for the hatch glass. I had not yet shared pictures of the new firewall insulation installed. When I applied the vinyl to the foam for the new headliner, and while the contact adhesive was in the spray gun, I installed them. I think they turned out to be very nice. I was held up on finishing the installation of the windshield wiper motor and mechanism because I was searching for a suitable replacement for the plastic "push clips" that hold the wiper bag end together. I found these at McMaster-Carr and they turned out to work nicely. After snapping them together, I just use small clippers to clip the extra portion of the post off. Additionally, I came across a forum thread in which @Captain Obvious described the proper function of the wiper arms. I had no idea that the round spring that always breaks was responsible for changing the off/resting position. I saw where some had bent the end of the existing, broken spring, so that it has a new "tang" to fit into the slot. I modified my spring today (third pic). It works perfectly - I can rotate it with ease in one direction and when I rotate in the reverse direction, I can feel the spring acting like a "one-way clutch". It grabs the eccentric piece you see and rotates it, which because of the offset, changes the length of the wiper arm assembly just a touch. This is what alters the "parked" position of the wipers to something just a bit lower than that of in operation mode. Cool! I believe this is the correct way to assemble the linkage to the motor, but I will leave the wiper off when I turn on the wipers to test them. Thanks for the tip @emccallum! Next, I moved over to gluing some more parts. Wiping the tool door cushions with lacquer thinner cleaned them up nicely. Then, I used a small brush and the same contact adhesive to install them. In this case, I didn't put adhesive inside the groove of the rubber cushions, as that would have been difficult and would have made a mess. Because I only put adhesive on the metal, I used the file clips to hold the cushions in place until the glue could set. While I had the adhesive out, I also glued the rubber blocks to the gas tank and installed the new gas tank sender unit:

-

Restoration of BringaTrailer 240z - HLS30-35883

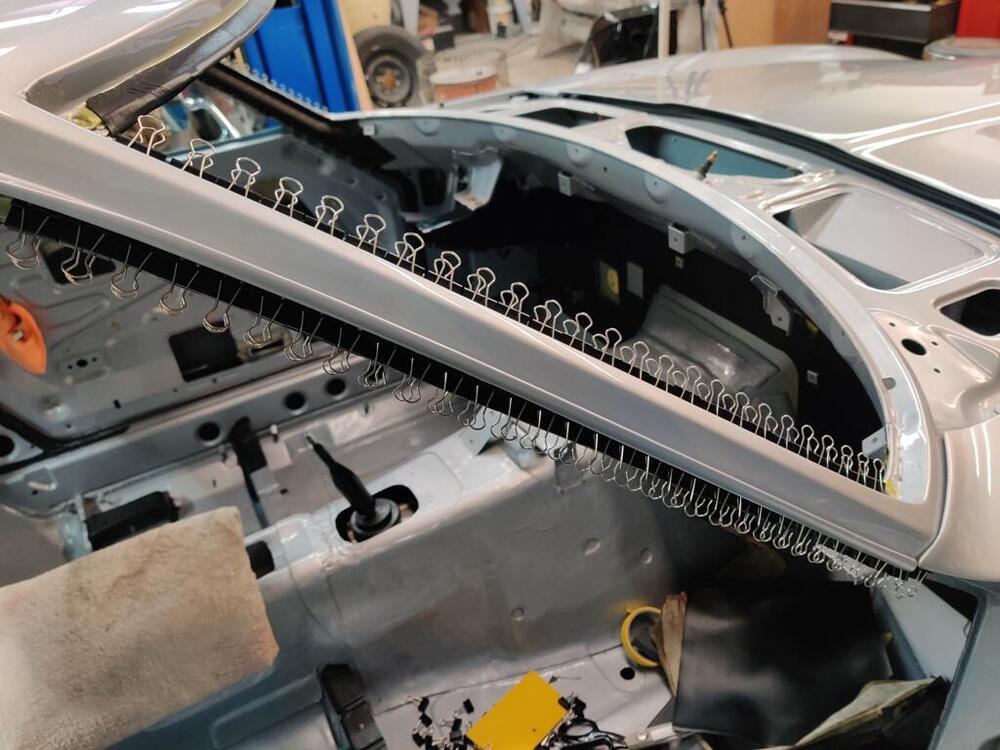

Thank you - very kind of you to say! Today, I picked back up with gluing interior pieces. Spraying glue is not something I have much experience with. So, I was nervous about installing the new headliner in the car. For example, I don't really know the right amount of glue to apply. Too little, and it might stick for a while, but fail later. Also, there is an amount of drying time that is important. Depending on the size of the piece being installed, you may have to wait a length of time, as the adhesive doesn't stick well when it is too wet. Or, if the piece is very large, you don't have to wait long at all, as it took some of that waiting time to apply the glue to the large surface area. There is a window of time where the glue transitions from wet... and a "tackiness" develops. After more time, the adhesive feels dry to the touch. And yet, if you put two pieces with seeming dry adhesive together, they can stick immediately... and not allow for pulling apart for "re-alignment". Over the past two days, I have found that waiting is necessary, but the pieces should be assembled when the glue is still at the "tacky" stage. At this stage, you can pull it apart and reposition a bit. If you wait until it is dry to the touch, then when you put the pieces together, they stick pretty strongly, and it is not going to go well if you try to reposition things. With all that weighing on my mind, I worked on cutting foam and vinyl pieces for the windshield header and side panels. I carefully examined the old foam and made new pieces that matched the thickness, width and length. Because some of the original pieces were only about 1/8th" thick, I bought that thickness of replacement foam. To match the thickness of the other original pieces, I stacked new strips of 1/8" thick foam, using just small amount of glue brushed down the center of the strips so they would stick together. From the old pieces, you can learn things, so you should keep them until your new pieces have been installed. For example, by looking at these indentations in the end of the old foam, I was able to eliminate any question about the correct location of the foam on the inside frame. I was also able to determine where there was overlap of original foam pieces. And that helped me locate the a-pillar piece of foam on the car in the same place as it was done by the factory. This foam compresses with very little pressure. While stacking 3 pieces high was a bit thicker than the original, it compresses easily, and will compress to the proper thickness when the vinyl is pulled and stretched over the foam. After getting the grey foam in place on all three sides, I masked off the frame area as described in the how to Restore you Datsun Z car book. Then, I took a moment to organize things so I could spray the inside of the roof of the car, and the back of the new headliner, and install the headliner in the car. When masking the rails, I made sure not any part of the rail surface was exposed to catching any adhesive. Even a tiny portion of the edge of the frame, if exposed, will subsequently collect some of the spray on adhesive. And it will become a problem when you go to position the adhesive covered back surface of the headliner in place. A touch of cement on the frame, if present, will touch the cement on the back of the headliner and "bite", causing difficulty with getting the headliner, up and over... and subsequently tucked behind the frame edge. Speaking of tucking behind the frame, I used a large plastic body filler spreader, which turned out to be a great tool for the job. There was a fair amount of force necessary to get the headliner to go from outside the frame to squished... and then, using the edge of the spreader... pushed inside the gap between the outer panel and the roof structure. The "extra" headliner material has to flatten out (behind the frame, hidden from view). Again, I was very happy when, like the gluing operation to adhere the vinyl to the foam to make the headliner, the installation of the headliner also went well. There were a couple of nerve racking moments, and 3/4 of the way through getting the edges tucked behind the frame, I was feeling some fatigue in my arms and soreness in my back from getting poked by various "not soft" parts of the transmission tunnel. From there, I started the next project: to install new vinyl onto the windshield header (front portion of the roof frame) and the side panels (side portions of the roof frame). I found it best to do things here different than Wick Humble's guidance. I was able to use a small brush and only apply adhesive to the underside of the back weld flange of the header. I let that dry a bit, and then positioned the header vinyl directly on that adhesive. I didn't use the welting at all, initially. The vinyl was simply hanging down from the back edge of the header, across the header's full width. Then, I aligned the white dot on the welting with the center of the header. I pushed the unglued portion of the header vinyl upwards and pushed the welting onto the back edge of the header, forcing the vinyl to tuck between the new headliner and the frame. The glued part of the header vinyl did not move as I did this. Only the non-glued part squeezed between the new head and the frame. At this point, the header vinyl is held captive by the welting, and it is ready to be pulled forward, and out through the windshield opening. It will need to be pulled with a good amount of force so as to compress the foam that is on the header, and create a tight, wrinkle free finished appearance across the entire header panel. And that has got me thinking... I don't know how in the world they did that at the factory - keep a lot of tension on the vinyl covering the header panel. The way the windshield goes in, the windshield gasket tends to push the vinyl on the header backwards. If the glue holding the front of the header vinyl were to not hold firm, the vinyl would be pushed back somewhat, allowing the header vinyl to relax... and be loose. If that happens, the finish look is not going to be nice, and who wants to pull a windshield BACK OUT, just to fix a loosely fitting header vinyl? I am not sure how I will proceed. But, I am thinking about buying a whole bunch of these, which I have seen other people use on other car restorations. I think I will need to apply the glue, and wait for it to dry... more than I have been, so that it will have the most strength possible. And then, I will pull the vinyl a good bit to the get material tight, and wrap it around the windshield weld flange, and clamp it in place very tightly to keep it from slipping back and causing a loose fit. And the glue will need to dry for at least 24 hours before I attempt to install the windshield. So, that is what I am thinking. Anyone else have luck using a particular technique?

-

Restoration of BringaTrailer 240z - HLS30-35883

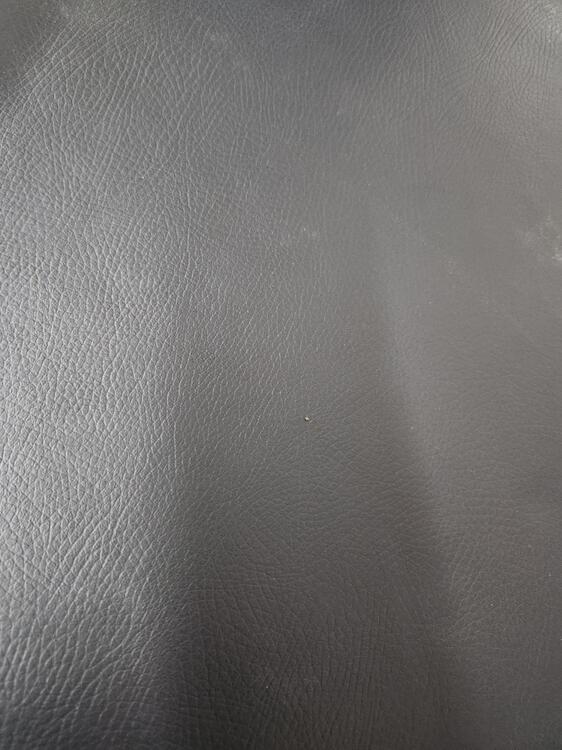

I spent many hours searching the internet and looking at vinyls, and I am pleased to have found a vinyl that looks similar to the original one for the headliner. I wasn't able to salvage my original vinyl, however, I think the headliner I made today looks quite similar. Original: As I said before, unfortunately, I wasn't able to glue the old vinyl to new foam without getting a lot of wrinkles: Unlike the old vinyl, the new vinyl has a cloth backing which makes it lay flatter and makes it stronger. I sprayed the contact adhesive out of a gun similar to a paint gun. The gun was purchased for doing this and it worked very well. The new vinyl: The finished product: While I had adhesive in the gun, I installed the new fire wall pads. I will put up some pictures of those being installed tomorrow.

-

Restoration of BringaTrailer 240z - HLS30-35883

That is a good idea. He's looking for a left window for me currently. I'll ping him. Thanks for providing a picture of the Banzai headliner. It does look nice.

-

Restoration of BringaTrailer 240z - HLS30-35883

I went through the shelves that had all my parts for the car plus lots of extras mixed in. I was trying to sort through some stuff so it would be easier to find things when I got ready. I looked at the headliner and decided I wouldn't use that on a car. I would just buy a new one. So out the door it went. It was on the brittle side but had been rolled up for a decade. But being on the bottom of the pile cracked it in a few places... I did find a number of things I had forgotten about!

-

Restoration of BringaTrailer 240z - HLS30-35883

During the time I spent on the car this weekend, I assembled the quarter glass windows into Nissan NOS rubber and into the quarter window frames. It is a rather difficult job, especially when using urethane window adhesive. I set them aside after assembling to wait for the adhesive to dry. I think it is likely that I will install the quarter windows in the car this week. Interestingly, I see that the etchings on my quarter windows date them to May and June of 1971. Combined with the door glass, the car has glass which was manufactured from dates in April through June. New McGard lug nuts showed up on Saturday. They are very high quality. I have used them on my other 240z for 30 years and they still look pretty close to new. I put them on along with the Panasport center caps. While it finishes the look, I kind of like the look of the hub dust covers which I had specially plated in yellow chromate so they would look like those with the original finish. I also worked on the differential. I have a separate thread where I am reporting issues and progress. I think I am much closer to resolving the issue with excessive backlash, and am looking forward to installing it in the car. I also attempted to glue the old head liner vinyl to new foam. Unfortunately, I got a few wrinkles in it. I also discovered two very small slits in the original vinyl after gluing it to the foam. I suspect that when the headliner was manufactured, the vinyl was at a much higher temperature and was pressed against the foam while under some amount of tension. As such, wrinkles would not form like I experienced here. So, because of these issues, I will not be able to use it. At this point, I will need to source a piece of cloth backed vinyl and glue that to new foam. It won't be original, and that bothers me, but I really don't see that I have any other option. I have been looking for a new old stock headliner for years, but haven't found one to be available.

-

Restoration of BringaTrailer 240z - HLS30-35883

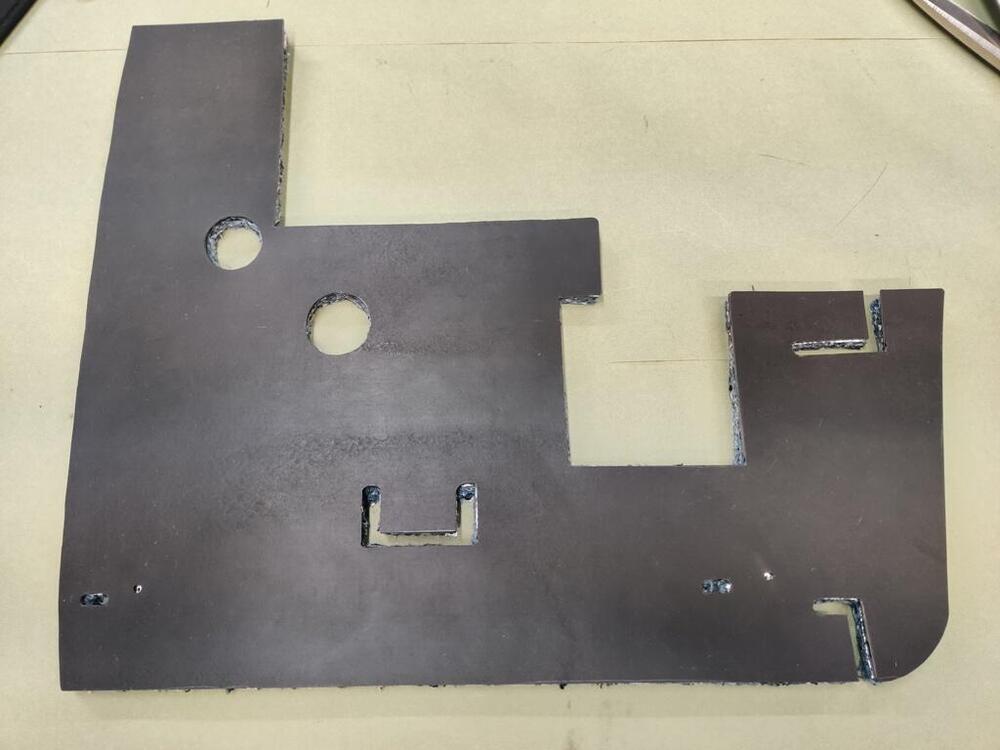

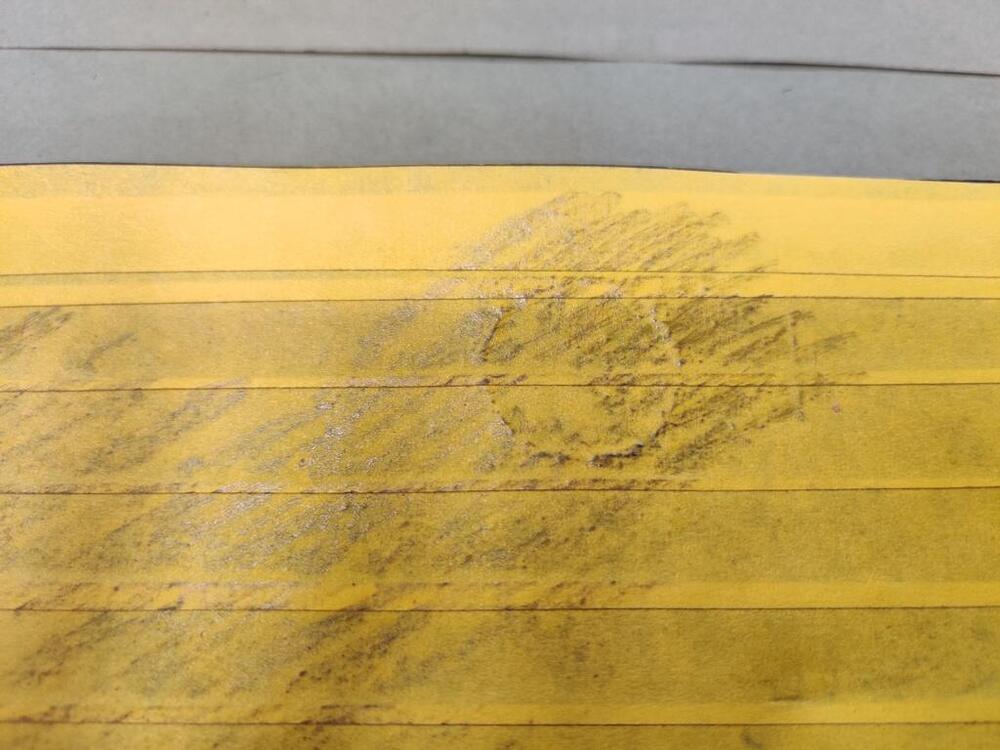

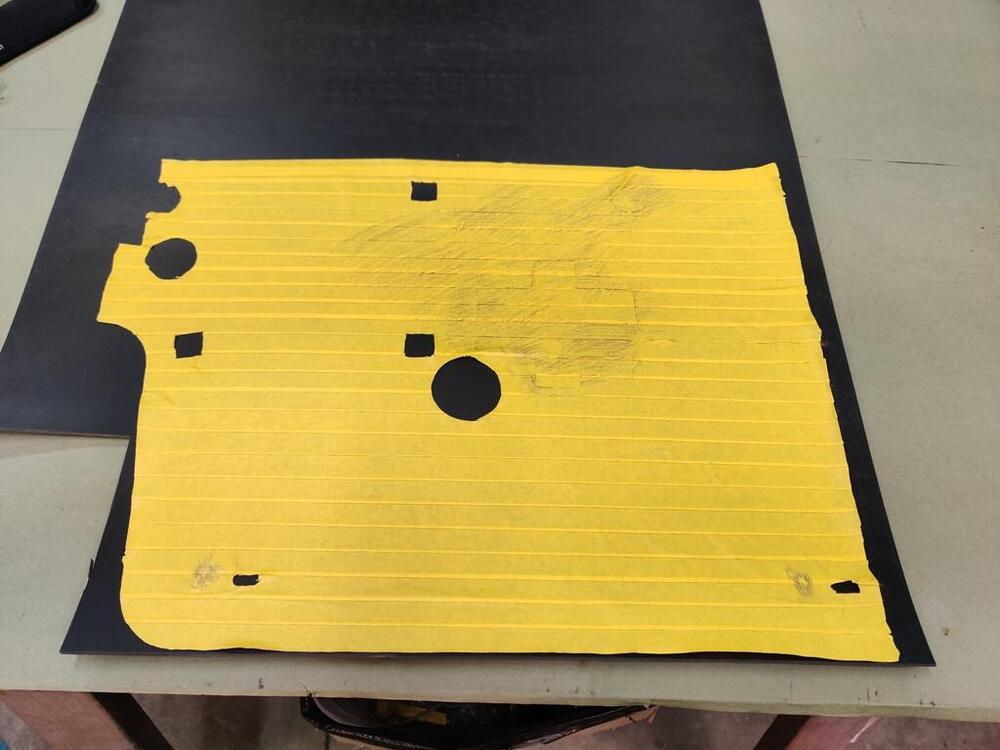

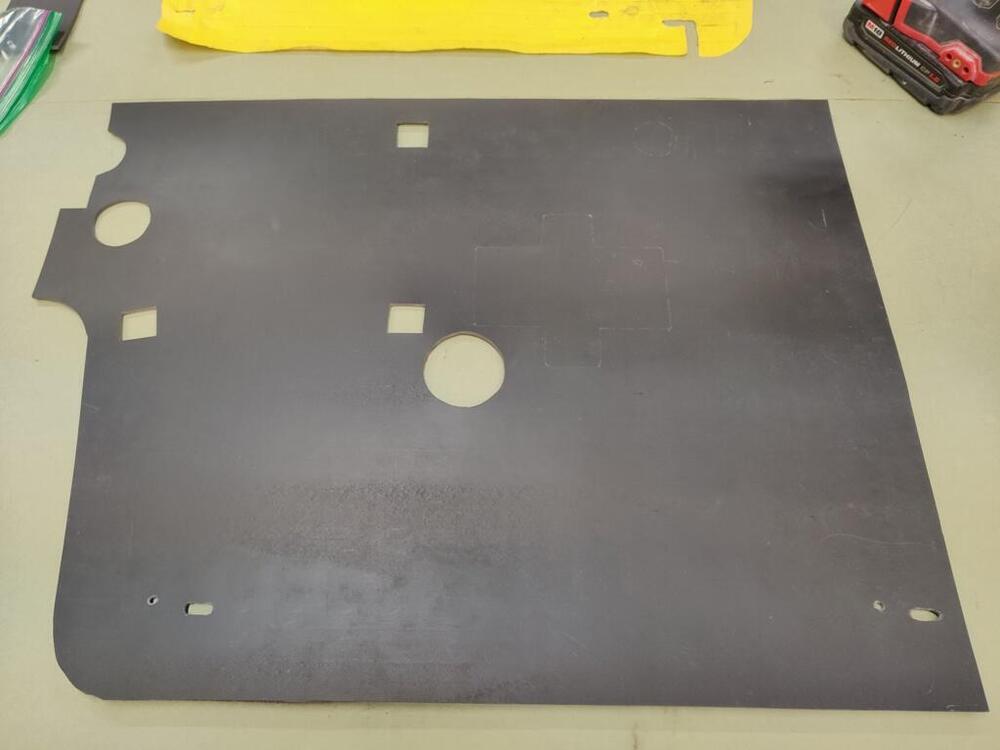

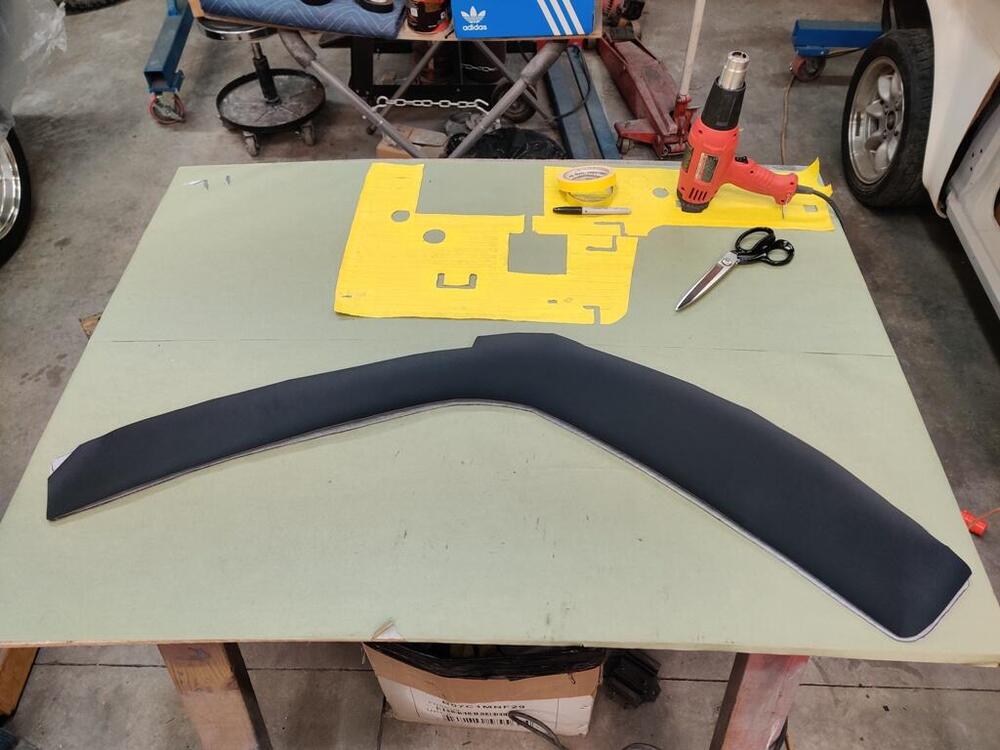

Today, I was able to finish cutting the materials for the left firewall pad, and complete fabrication of the parts to the right firewall pad as well. For the right pad, I started by heating it up with a heat gun to assist with flattening the bitumen - it had several wrinkles. I used my hydraulic press plates to flatten and cool the bitumen. They are heavy and also helped to cool the bitumen while holding it flat. After getting it reasonably flat, I applied tape and trimmed it so it could be used as a template. As before, I peeled it off of the old and stuck it to the new material. Then, I trimmed the new material to match the tape template. When the new pad was made out of butyl rubber, I laid it on top of the new insulation and marked the cutouts. I used a black Sharpie to mark the foil. I think it took about 3 and half hours to make this part. Then, I grabbed the old header and A-pillar vinyl. Unfortunately, it would be too difficult to reuse because of all the glue on it, and some tears on the left piece. I found some vinyl online that looks kind of similar. Before cutting the new piece, I used the heat gun again to get the old pieces as straight as reasonably possible. Then, I drew on the backside of the vinyl, providing a generous amount of extra on all sides. I cut the piece for the header out first, then one of the A-pillar pieces. Then I flipped over the new A-pillar piece and used it as a template for the other A-pillar piece. Lastly, I retrieved the old headliner vinyl (with foam stripped off of it) and the new foam piece I bought. I am going to attempt to glue the original headliner vinyl to a new piece of foam. I don't have high hopes that it will work well, but I will give it a try. I bought enough of the foam to make a second headliner. If I have to, I will attempt to find a new piece of vinyl that will be suitable for a headliner, and glue it to this foam.

-

Moving Seat Belt reels to strut tower like 77-78 280Z - on a '75 280Z

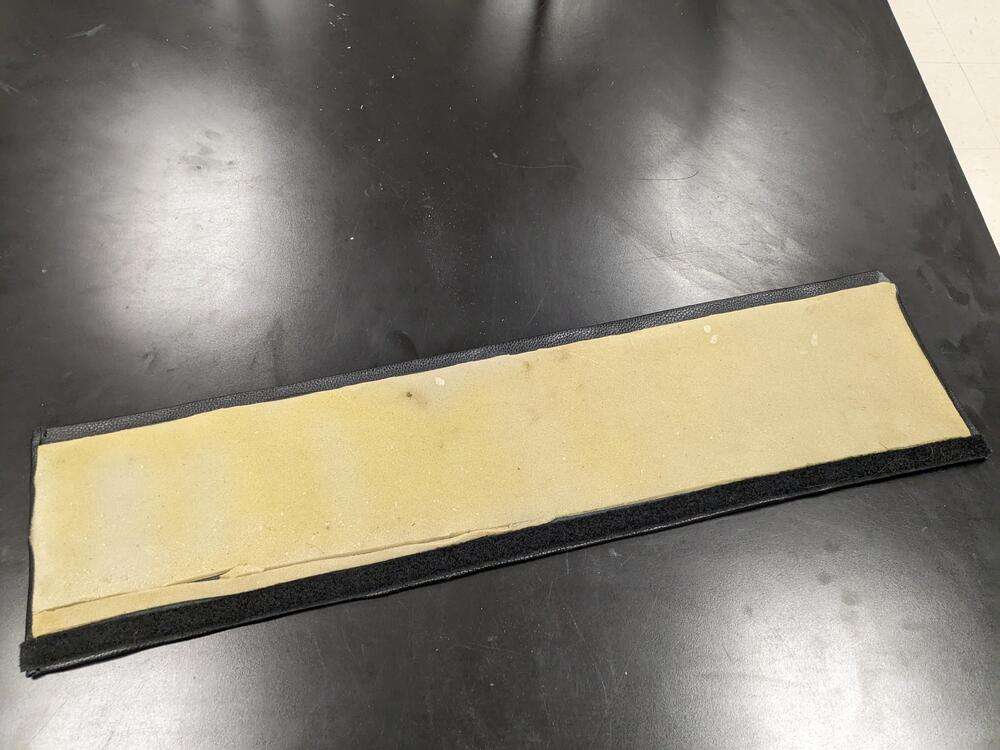

1/4" Skrim coated foam (left over from a Volvo headliner job years ago) faux leather padded sleeve. Velcro fastening

-

1973 Rebuild

Working backwards, the insulation kit is from Collectors Auto Supply. I bought a box of Dynamat to augment the kit because I didn’t feel that it was quite enough, particularly the roof, which you have to completely cover so you don’t see lumps through the headliner. No, I didn’t presssure test the vacuum tank. I did a thoughough visual inspection, which, granted, may not be adequate, but I’m trying to get the engine stated asap, so I’ll find out if it’s leaking long before the interior panels go in. I decided to keep mine in the car after reading that the system allows vapors to expand and condense in a way that maintains a certain amount of pressure in the system so that two things happen: 1. The fuel stays in the front of the car when the car is nose up on an incline so there is no delay in it arriving at the carburetors when starting, and 2. You don’t get sprayed with gasoline when you open the gas cap, hence the valved cap. The routing is pretty efficient. The only way they could have avoided it is not having a port on the left side of the car (skinny end of the tank). Also, the hoses have to route in a way that the vapor tank lines don’t have a low spot that causes fuel to pool in the hose. You’ll see what I mean when you do yours. Yes, there are a lot of hose diameters. I don’t know if it’s true for the hoses, but I’ve read that the hard lines are designed to keep pressure consistent and correct for the size pumps and carburetors in the car, meaning the return is the smallest. The vapor tank is probably also optimized for flow, so big fat hoses. The hose that is going to give you the most trouble is the hooked one that goes through the frame from the vapor tank to the top of the gas tank. It’s one or two millimeters too small. If you get the same hoses I bought, you’ll need 5mm x 3ft, 7mm x 3ft, 9mm x 10ft, 12mm x 10ft, and 17mm x 10ft. I also bought 3 feet of the 3.5mm just in case I need it later. Yes it’s weird that they sell metric hose SAE lengths.

-

Z's on BAT and other places collection

Looks like pretty rough shape.. The headliner, visors, and mirror look good. Solid steering wheel appears correct just missing paint.

-

280z storage compartment inserts

Someone is buying, there are 7 items in his sold listings. The padded inserts are just spray adhesive stuck in there. Kind of like the headliner. I have some out if you wanted measurements.

-

1971 HLS30-14938 "Lily" build

So I got the headliner trim in Gonna have to pick up the pace to be ready for Zcon 2024 Momma is starting to crack the whip

-

Interior roof and pillar trim

So I need some advise. I need to do the vinyl roof trim and the A pillar trim in the car. If I had been thinking, I would have done this while it was on the rotisserie, but I wasn't! I did the headliner this way. I don't know why I didn't do the rest then... So which order do the pieces go in? Sides first, then windshield header? Any pictures of how the ends are folded or detailed? What is the best way to go about it? Foam onto the vinyl first or foam on the car first? Glue applied to the vinyl or onto the car? Spray glue or yellow contact cement? I have been procrastinating on this but it's time to get it done. Thanks for any help C

-

Dome Light Repair

I searched for "water proof push button switch", I ruined one of the 5 when I was fixing this, so might be nice to have a few spare... Its pretty hard to open the OEM switch without the plastics breaking, I find it to be too brittle, there is a spring and some sort of rotating dial/mechanism in there. I would be surprised if they can be repaired... I guess its a switch, thin metal, when it weathers and builds resistance its going to heat up and melt. https://www.ebay.com/itm/323539395923?hash=item4b54736553:g:Q8wAAOSw8Ehb49~s&amdata=enc%3AAQAIAAAA0EZ442YEWVNV2hOaEEz5Gnxia76JJ6I6kY34KBMUMNHDsP6tz2gOh%2BAf0iPPVVIejs9%2FrhLedyvMf3hh9aThRcHU75wUaY8UCsZBcgIioyTUfi%2Fy72VdBqoKzsSrDjzYkLWsOhrKvSA8bccwn17DDATenZis8COZwZYaUbgPsLjT%2BizXifWSPO8PQJrTszkzZeJ238GdaA1onX13HWOjzvJoOvHS0kO13BvB5DWpy8t9Y%2FMFS8PZPtRT6d2Wajfc1p0ZmXroMd8%2BnKT2mq94ZYU%3D|tkp%3ABk9SR-L4xN_6YQ I should install the damn headliner and finish putting the interior together.

-

Restoration of BringaTrailer 240z - HLS30-35883

-

Restoration of BringaTrailer 240z - HLS30-35883

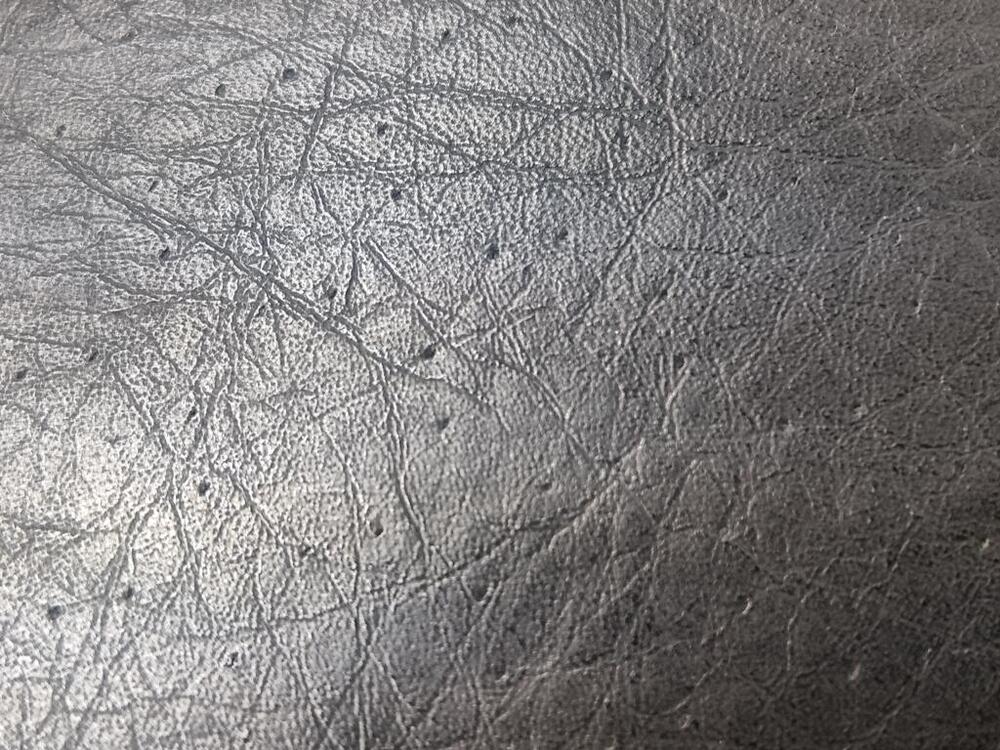

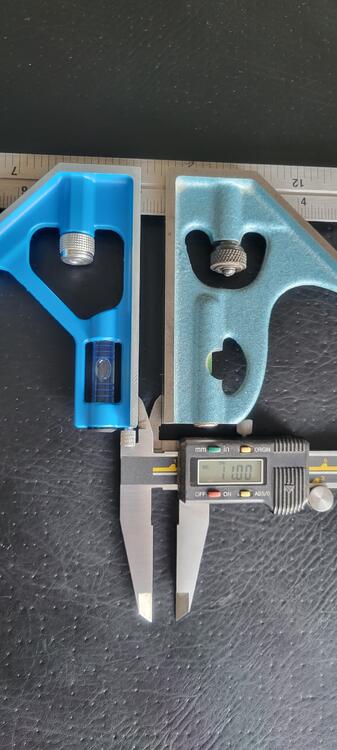

Here is the measurement of the OE headliner from my 7/70, overall thickness 11mm (.433") and best I could measure the vinyl thickness is 0.3 mm (.012") Here's a pic showing the grain and "stipple" pattern with a tape measure. I call it stippling as it's more of a depression, definitely not a hole that goes through the vinyl.

-

Restoration of BringaTrailer 240z - HLS30-35883

Does the replacement headliner from Banzai have the holes?