Search the Community

Showing results for tags 'weber'.

-

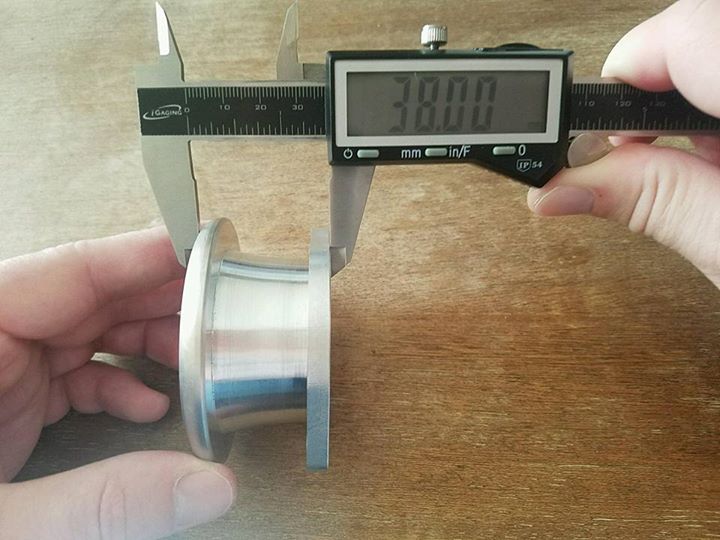

I have a set of 6 new, never installed, 45mm velocity stacks made by RHD Engineering. RHD one-piece trumpets are machined from solid 6061 billet Aluminum. All trumpets are 38mm tall and are a correct fit for 45mm Weber DCOE, DHLA, IDA and IDF. Each stack has a rolled lip to minimize turbulence air and ensure maximum air flow potential! I am asking $150 for the set, which is a good discount from what they cost! **Stacks are shown as-is and do not include the mounting hardware. Let me know if you have any questions or check out the RHD website for additional specs: http://racehead.com.au/products-page/velocity-stacks-and-spacers/42-x-38-trumpet/

-

Complete set of triple Weber 40DCOE carburetors ready to bolt on. Includes velocity stacks, air filters, choke cable and throttle linkage all connected and ready to install on your motor. Also includes a modified throttle spring mounting bracket and a Ferrari throttle spring recommended by another Z enthusiast that had triple Weber's. Works Great! I removed the Weber's from the 240Z I had them on after I missed a gear, over revved the motor and bent an Exhaust valve. I pulled the motor and decided to rebuild it. When it was completed we put the original SU's back on because I wanted to sell the car and get another one with less rust. I wanted the Weber's for the next Z I bought. Well, I never got another Z car but instead defected for a Porsche 911. (Also have an original orange 240 Z air box. Please see other post.) $1,150.00 + Shipping

-

The Spruell Motorsport shipment just arrived with the stronger Weber 40 DCOE Throttle Springs. These springs are used to firmly close the throttle plates shut. This ensures consistent performance as explored and discovered in this thread: http://www.classiczcars.com/forums/carburetors-s30/48969-weber-internal-spring.html For reference, here are the Weber part numbers: 47605.012 Weaker 47605.027 Standard 47605.009 Stronger I decided to measure the spring constants of the springs I had on hand for reference: ?????????? (is from Pierce Manifold sold as 47605.009 BEWARE) New 713.2 N-m 526 Ft-Lbs 47605.027 Used 1,634.4 N-m 1,206 Ft-Lbs 47605.027 New 1,669.2 N-m 1,231 Ft-Lbs 47605.009 New 2,203.7 N-m 1,625 Ft-Lbs I am not sure of the age of the used standard spring but it has not aged much.Clearly Pierce sent the incorrect spring.The stronger .009's are ~ 33% stronger

-

I have been having issues with my OER SK 40mm carbs. The problem is very elusive and I have not been able to find the source. I will do my best to describe the problem and I am willing to clarify if needed. I am going to refer to carb(#1) as cylinders 1 and 2. Carbs #1 and #3 are perfectly fine, it is carb #2 that is acting up. I started to sync the carbs, first by disconnecting all the linkages. I managed to balance #1 and #3 using an unisyn tool. However, #2 (cylinders 3 and 4) would be run leaner than the others. I unscrewed the idle mixture screws for #2 a few turns, and it leaned out even more resulting in popping out the carb and a nearly white spark plug. Also the #2 would draw a lot more vacuum than #1 and #3, and I unscrewed the idle speed screw for #2 and #2 still ended up drawing a lot more vacuum. #2 has enough vacuum that when I touch the unisync tool on #2 the engine will nearly die and then fuel spills out and then rpm picks up a lot. However, I got the car to idle smooth enough by tuning by ear and I would hold rpm at 2.5k and 3k and the #2 carb would cough and the exhaust would back fire, checking the plugs (cylinder 3,4) they were even whiter than at idle. Meanwhile the other plugs were a nice brown. This issue has bee driving me mad. Issues list: 1. carb #2 runs lean 2. (all linkages disconnected)(speed screw backed off 100% for #2) carb #2 still draws more vacuum that #1 and #3 3. Carb #2, touched unisycn tool the engine nearly dies, fuel drips out of throat, engine speed rises rapidly 4. #2 meaning cyl3,4 mixture screw(1 turn), nearly white plug, all others are a nice tan 5. #2 mixture screw(2 turns), completely white plug, all others are a nice tan 6. rpms held at 2.5k and 3k carb #2 cough and exhaust back fire 7. rpms held at 2.5k and 3k carb #2 (plugs 3,4) are bone white, all others are a nice brown 8. no binding in the linkages, linkages move very smoothly 9. Sprayed carb cleaner on all joints and seals, no increase in rpm 10. float levels all set to the same factory settings

-

I'm setting up triple 45s with the cannon manifold and conversion kit and I hit a snag. The plate that the throttle linkages connect to on each carb is so close that the head of the bolt holding them together hits a mounting point on the carb. I was thinking I would just flatten out this point since it's not needed and move on with my life. Do I just have it set up slightly wrong or is this common?

-

Wondering if I should be concerned with this... I am setting up the 45's on a canon manifold. This model of Weber (45 DOCE 9) does not have a Progression Hole inspection port and hence I am confirming the location of the throttle plate and progression holes prior to mounting the carbs to the intake manifold. I have noticed on one carb that the return spring (and location of the throttle plate) is a little bit" lazy", as the throttle plate will still allow for one progression hole to remain uncovered unless I apply a small amount of pressure to the throttle plate spindle. I do not have this issue with the other two carburetors. I am wondering if I should be concerned about possible on issues once I do eventually fire this thing up? Any thoughts are appreciated.

-

We just bought a 1974 260z with triple carbs. However, they are locked up and unusable. Is there a solution to unlocking them? Also, if we have to replace them, what is the difference in the Weber triple carb and Mikuna triple carb?

-

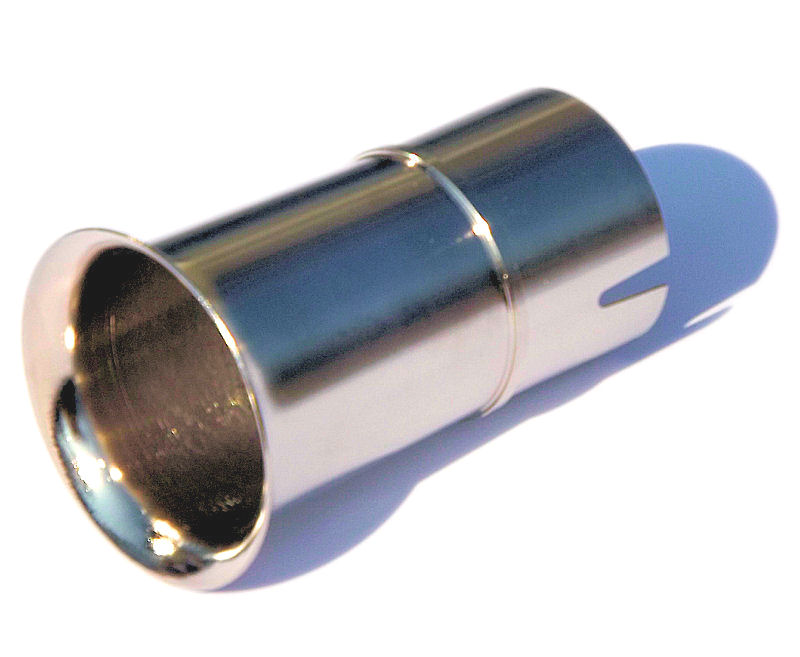

I've gone through the forums and cant seem to find a bottom line answer to this. I have Weber DCOE 45's on my 240 and I just purchased some new stacks (pictured in red). These stacks are the bolt-on style and do not slide into the carb, like some that I am seeing (also pictured). 1. Will my bolt-on stacks work with no issues? 2. I read that the "slide-in" type stacks help hold the venturi in place, is this true? 3. I also read that the "slide-in" type stacks do something with the choke plate, is that true? Thanks, Jeff

-

Disclaimer: I am by NO means a Weber Pro and this post is still a WIP (Work in Progress) Hello, my name is Mike and I've recently tackled my first set of Triple DCOE Webers project. Now, I spent hours reading all the manuals and following a few guides online, but none of them were particularly methodical in their approach and often just led to more confusion. I'm putting this guide together to, hopefully, help others who might not have much experience with these carbs or for those who (like me) prefer a Step-by-Step approach to figuring things out. This guide has been made possible with the help of those more knowledgeable than me. Thanks guys - you know who you are! If there's anything I need to clarify or add, let me know. Table of Contents I. Documentation II. Useful Links/Parts/Accessories III. Prologue IV. Choke/Venturi V. Main Jets, Emulsion Tubes, Air Correctors & Idle Jets VI. TBD I. Documentation DCOE Weber Carburetor Top-View Layout Weber Factory Tuning Manual - Download Link Power Tuning Webers (Des Hammil/Veloce Publishing) - Download Link Selection and Tuning of DCOE Weber Carbs (David Andrews ) - Download Link Weber DCOE Tuning Manual (Philippe Boursin) - Download Link II. Useful Links/Parts/Accessories http://www.redlineweber.com/ http://www.piercemanifolds.com/ http://www.carburetion.com/index.htm III. Prologue - The First Date First and foremost, it is essential that you know what you're working with. Setup a date with your newly acquired friends and spend a romantic evening just getting to know each other - perhaps light some candles and pour some wine while you're at it. In order to tune them properly, you need to know what sort of equipment your carbs are packing. IV. Choke/Venturi - Step One - Removal Let's start off by determining the size of the chokes/venturis. (If carbs don't have filters on them, skip to Step 1D) If the carbs are already out, the easiest way is to shine some light down the carb and see if you spot the engraved number. If you can't see the number or if you want to replace the chokes, then follow these steps. 1A - Unscrew the airbox/filter (If applicable) 1B - Underneath there are four (8mm) bolts holding in the housing. I already took off one of the studs. 1C - Remove Gasket (If applicable) 1D - Unscrew the this little fella (11mm) sitting on the bottom corner of each side of the carburetor. This holds the auxiliary venturi in place. 1E - Once the screw is removed, the aux. venturi should slip right out. 1F - Make a note of the little indent where the screw holds the aux. venturi in place. You're gonna have to put it back the same way for it to seat properly 1G - You should be able to see the chokes now, but we're gonna replace the 28's with a different size. 1H - Unscrew this fella (I used a flathead) to allow the choke to slide out. 1I - If you're having some trouble getting the choke/venturi out, then open the butterflies and push it out from the opposite side. It'll otherwise slide out IV. Choke/Venturi - Step Two - Assembly Alright, so now we have removed the choke - it's time to replace them! Here's the old 28 next to the new 34 that is going in. 2A - See these notches? You want to make sure that they line up properly in the carb. Looking at the carb from the front, the left choke lines up at 12 & 3, while the right choke lines up at 12 & 9 (Left choke lined up at 12 & 3) 2B - Re-insert the screw and make sure it sits firm. I had some trouble getting the right angle on some of them, so just make sure it's lined up properly. 2C - The aux. venturi should slide right in. Remember that little indent from before? Make sure it lines up properly with where the screw goes. 2D - Screw the little guy (11mm) back in and double check to make sure the aux. venturi is seated properly 2E - Do one final inspection to make sure everything is sitting right and then continue to put your gasket and filter back on. Personally, I went with these stacks. They slide right in and uses little clips that slide into the studs to hold them in. V. Main Jets, Air Correctors, Emulsion Tubes & Idle Jets WIP - Work in Progress

-

29 downloads

This is an interesting manual that I came across while going through my files. It's got a parts list of essential special tools and a complete description of how the carbs work. It also includes details about finding faults and fixing them. Hope this is a helpful manual for some of you with Webers.Free -

- 1 review

-

- carburettors

- dcoe

- (and 4 more)

-

Hey y'all. Sorry, I don't know much about forum ettiquette as this is the first one I've joined.The guy said that everything under the hood was perfect, but after driving it for a week, I'm seeing that the carb intakes are leaking gas and the gaskets leading into the engine are wet with gas as well. I'm kind of a novice (at the Forum thing as well as owning a datsun/working on my car) so any pointers would be appreciated! I really want to do the car justice! - Josh Info: Original Engine - 90k miles Idle - 1500, sometimes dips down to lower 1000s Anything else that's relevant?

-

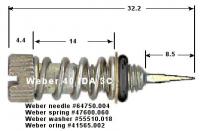

I am starting to look deeper into the claim that later DCOE's Idle Enrichment Screws are typically turned-out further. The details in the screw interface to the carb body distill to: 1. For the same flow: A narrow tapered needle needs to be tuned out further than a wider tapered needle if the orifice size is the same. It is proportionate to 1/tan 2. For the same fuel flow, a needle with the same taper needs to be turned out more from a smaller orifice than for a larger orifice. So to compare an early carb's Idle Enrichment Screw turn-out to a later, one must know the taper of the needle and the orifice size. In another post I measured the threads on early and later DCOE Enrichment screws and it was 0.8 for both. The part number for 40DCOE151 Enrichment screws is 64750.003 The DCOE151's I am tuning have this needle: 64750.004 64750.001 is stated to be "38 degrees" and for "early DCOE carbs" 64750.002 is the air bypass screw From the above, the 003 and 004 do seem narrower than the early 001.

- 2 replies

-

- dcoe

- enrichment

-

(and 3 more)

Tagged with:

-

Good morning all Z club members, glad to have found this site. I have a 74Z for sale and would like some feedback. It has appx 55000mi, is slightly modified with 3 40dcoe weber carbs, headers, freeflow exhaust, mulholland suspension, chrome wheels. Other than these it's stock, with a little rust. Any suggestions on what to ask? Thanks in advance, Harv Here's a pic

-

I have tried to rebuild carbs for the first time...not too bad, but I get a hesitation/ stall out when first accelerating then it runs great. Any advice or know anyone in South Florida who rebuilds them? Cheers!

-

The DCOM series of weber carbs were the replacement carbs for the Weber DCOE production. The Italian Weber DCOE production lines ceased in the middle of the 1980's and these carbs were the next evolution.Weber didn't forsee though that the electronic fuel injection systems would replace carburetors. The DCOM has improved performance over the DCOE carbs and more lasting on/off use due to the perfected acceleration pump diaphragm and adjustable pump lever. DCOM carbs will bolt on any standard side draft weber 40 DCOE carburettor manifold and uses the same inner parts, namely jets,needles, seats and floats as the former DCOE carbs. I believe this information to be very accurate however I wouldn't like to be quoted on it haha. Hope this has been useful Matt

-

- carbs

- carburetor

-

(and 3 more)

Tagged with: